Winter is coming, and it’s time to launch new velvet and wool products. The editor found that there are many brushed fabrics on the market now, which are loved by many people. But many people think that brushed fabrics are brushed fabrics, but is there really no difference between the two? Today, let’s talk about this matter.

We have learned about sanding before. Click to review: What is sanding fabric, do you really know? Then let’s talk about sanding in detail.

The following officially begins:

First of all, sanding ≠ sanding.

01/

What is brushed fabric?

Nubuck fabrics are generally made of 30-count or 40-count twill fabric as the base fabric, and are then raised through mechanical friction. Brushed fabric is a kind of high-grade combed cotton, which is dyed and finished first and then lightly sanded, giving it a unique style.

02/

Why is brushed so popular?

Nubuck fabrics have been loved by consumers as soon as they were launched. Because it feels soft and comfortable, has rich texture, strong drape and is easy to care for. Fabrics treated with sanding technology will have a layer of fine sanding on the surface, just like the down on small animals, which is thin and soft. The fine fluff creates a space between the skin and the fabric, which buffers the heat emitted by the human body and isolates cold air.

Therefore, the warmth retention is twice that of ordinary fabrics, and it even has the effect of “the more you sleep, the warmer you get”.

In addition, due to the unique craftsmanship, the brushed products will not fade or pill, which is much better than ordinary cotton fabrics and weighs less. Much thicker than ordinary cotton materials.

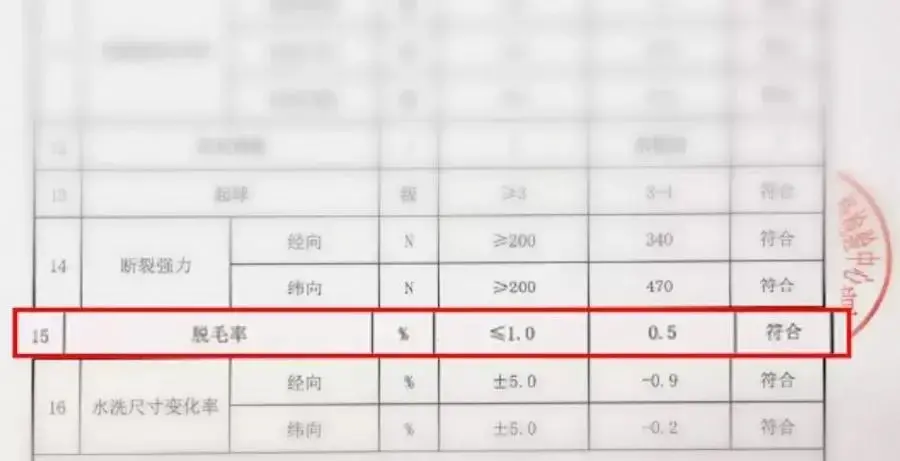

Of course, brushed fabrics also have their own shortcomings – lint. With today’s technical conditions, it is impossible to avoid hair loss. However, as long as the hair loss rate is within the range allowed by national regulations, this is a normal phenomenon.

03/

Care for brushed fabrics

The characteristics of brushed fabrics mean that they are difficult to care for, so we need to be extra careful when cleaning. It is not recommended to turn on the strong mode for machine washing, and the washing time should not be too long. Clean the lint in time after washing to avoid prolonged exposure to the sun.

The basic knowledge of brushed fabrics is almost finished. Next, let’s talk about brushing and brushing.

The common points between grinding and sanding:

From a process perspective , there is not much difference between the two. The process of using a sanding roller (or belt) to grind out a layer of short and dense velvet on the surface of the fabric is called sanding finishing, also known as sanding finishing. The function of sanding and sanding finishing is to produce fluff on the surface of the fabric.

The difference between brushing and sanding:

Sanding is generally 21 A fabric made of single-sided khaki fabric as the base fabric (khaki fabric is a fabric mainly blended from cotton, wool, and chemical fibers) and raised through mechanical friction. It feels thicker and has a strong suede feel.

The feel of grinding is not as thick as that of sanding, and the suede feel is not as strong as that of sanding, but the raising effect is more delicate and the suede surface is more delicate.

As for a four-piece set, the brushed four-piece set is heavier than the brushed four-piece set, and there is a certain price difference between the two.

In addition, sanding is a nylon-polyester composite yarn. The fiber contains a certain amount of nylon components, and then under certain conditions of alkali, temperature, and related additives Therefore, there are new requirements for the dyeing and finishing process and dyeing materials. It is also necessary to consider other internal quality parameters. It is not easy to achieve high quality.

The general grinding is all polyester, which is a general fine fiber, and the dyeing and finishing process is simpler.

Have you ever used nubuck products? How do you feel? Leave us a message in the comment area~