Pictures for reference

1. The history of polymers –

Polymers are closely related to our lives. An important role is the various fiber materials in life. Papermaking, frozen tofu, and silk were all daily uses of polymers by ancient Chinese people.

In the early 19th century, the German chemist Weller invented organic chemical reactions, crossing the gap between inorganic chemistry and organic chemistry. In 1845, Schönbein discovered the first plastic – nitrocellulose (nitrocellulose). In the 1860s, John Hyatt invented celluloid, which is also a flammable material. There are still some ping pongs today. The ball has been adopted. Polymer chemistry has become a key research object, with phenolic resin (insulating electrical components, 1907), urea-formaldehyde resin (electric jade, mahjong, 1918), polyethylene (1935), nylon (the first synthetic fiber, 1930s), etc. Discovered and mass produced.

After the discovery of nylon, synthetic fibers entered people’s field of vision. In our daily lives, fabrics are often referred to as pure cotton, chemical fiber, etc., which means that fabrics are divided into two categories: natural and synthetic. This is actually biased. Fibers are divided into four types: natural fibers, synthetic fibers, man-made fibers and inorganic fibers. Natural fibers such as cotton, linen, silk, wool, and asbestos, synthetic fibers such as polyester, nylon, spandex, polypropylene, acrylic, vinylon, chlorine, fluoron, aramid, etc., and man-made fibers such as viscose and acetate. , cupro fiber, etc., inorganic fibers such as glass fiber, metal fiber, etc.

The definition of plastic and rubber: if the glass transition temperature Tg is higher than normal temperature, it is called plastic. It is relatively strong at normal temperature. If Tg is lower than normal temperature, it is called rubber (or elastomer). Plastics, resins, and rubber are all polymers.

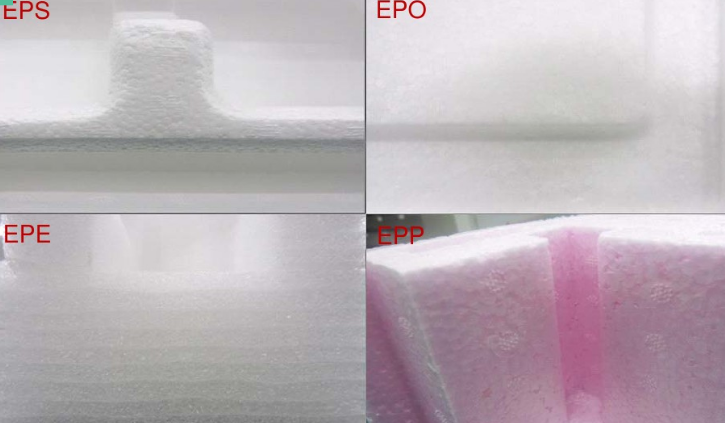

Pictures for reference

2. Introduction to common fibers

Polymeric fibers will only produce strength when the degree of polymerization is above 200. The higher the degree of polymerization, the higher the strength and melting point, which generally reach Strength above 2000 is better, and will reach a critical point later.

1. Polyester PET – the stiffest fiber

Polyester is the synthetic fiber with the largest output today. my country’s largest polyester factory has an annual output of more than 4 million tons. The full chemical formula is polyphenylene. Ethylene glycol diformate, referred to as polyester fiber, also called PET, is widely used in spinning and plastic containers. According to two different methods of quenching or annealing, transparent amorphous and opaque crystal products can be obtained respectively, so PET can be divided into transparent and opaque.

Polyester is crisp and wrinkle-free, does not rely on ironing, and is easy to dry. It is also called really cool or really good. It is a major source of fiber for today’s clothing. Among synthetic fibers, polyester has better UV resistance and is often made into parasols. Because it does not absorb moisture, one side is wet and the other is dry when it rains.

2. Nylon PA – the strongest fiber

Nylon is the second most produced polyamide synthetic fiber, also known as nylon. Common nylon 66 is the polymerization of hexamethylenediamine and adipic acid. An ancient saying goes, “Three days of fishing, two days of drying the net.” In the past, fishermen used fishing nets made of cotton and linen, which were highly hygroscopic and weak in strength. Therefore, after each fishing trip, they needed to spend time drying and repairing before going out to sea again. . Since the emergence of nylon, it is lightweight, strong, corrosion-resistant and has low moisture absorption, making it the first choice material for fishing nets.

In other fields, nylon is often made into various zippers, buckles, airbag fabrics, parachute fabrics, etc. However, nylon has the worst UV resistance, and the molecular chains are easy to break in the sun and cannot be used. It is light-resistant, so it is generally used as an umbrella. It dries worse than polyester, so both sides will get wet.

3. Spandex PU – rubber fiber

Rubber cannot be spun and can only be cut from rubber sheets, so its application is limited. Spandex is a polyurethane (PU) material. Its elastic load capacity is 7 times that of rubber, its wear resistance is 2-10 times that of rubber, and it has good anti-slip properties. It is widely used in elastic clothing textiles. The elastic tape wrapped around the wooden handle of a tennis racket is non-slip and elastic, and is also made of spandex.

Lycra is a trade name of DuPont. It is a type of spandex with a stretch of up to 500%. The price is much more expensive than ordinary spandex. Clothes made of Lycra will have a triangular hangtag, which has become a symbol of high quality.

The polyurethane fiber swimsuit was born in 1974, which can effectively prevent too much water from flowing in through the gaps after the swimsuit is stretched. After that, shark skin swimsuits appeared in the Sydney Olympics, which shocked the sports world. The Beijing Olympics broke the news because of the shark skin. 34 swimming world records. At the 2009 World Swimming Championships in Rome, a high-tech swimsuit that was stronger than sharkskin appeared, the Italian Jaked swimsuit, which broke more world records than the Beijing Olympics. After that, the Swimming Federation canceled high-tech swimsuits. The material of Jaked swimsuit is polyurethane PU, which costs 4,000 yuan per piece. It requires the help of several people to put it on. It usually takes the 4th or 5th time to put it on to achieve the best results.

Polyurethane is also the outer material of modern football and the main material of plastic track. It has good stretchability and elasticity.

4. Polypropylene PP – the lightest fiber

Polypropylene is polypropylene fiber, also known as polypropylene. It looks like plush silk or cotton, and its density is the lightest among chemical fibers. , strongIt has high moisture absorption and low hygroscopicity. This material is used in cigarette filters to filter harmful tar.

Polypropylene is strong and durable in the plastic field and is widely used in plastic water cups.

5. Acrylic PAN – artificial wool

Acrylic (polyacrylonitrile fiber) uses acrylonitrile as the first monomer (>85%) and is copolymerized with a small amount of other monomers made of polymer.

In 1950, DuPont took the lead in industrial production. Acrylic fiber is fluffy, soft, and its warmth retention is comparable to that of wool. It is not easily destroyed by bacteria and insects, changing the view that “wool comes from sheep” and eclipsing natural wool. However, acrylic fiber is prone to static electricity due to friction, easy to pilling, easy to absorb dust, and is not resistant to dirt, so it is not suitable for fabrics and underwear that are often subject to friction, such as socks and gloves.

6. Vinylon – artificial cotton

Vinylon is the trade name of polyvinyl formal fiber. Its appearance and feel are similar to cotton. It is light to wear, strong and durable, and is often used for Geotextiles, filter cloths, cables, etc., are blended with cotton and are called “dimensional cotton”.

7. Viscose fiber – rayon

Viscose fiber is a spinning solution formed by processing cellulose (pulp) extracted from wood, cotton linters, etc. After maturation, viscose fiber can be obtained by further processing and drying after degassing, spinning, coagulation bath, regeneration. Because it is processed from natural fibers, its chemical composition is the same as cotton fiber, but its wear resistance is not as good as cotton, its elastic recovery is poor, and it is not wear-resistant, so it often needs to be blended. Rayon can also be used as wigs and is very cheap compared to wigs made from real hair.

A variety of other chemical fiber varieties are not discussed in detail (such as polyethylene PE, polystyrene PS, polycarbonate PC, polyvinyl chloride PVC, expanded polystyrene EPS (foam plastic), expanded polyethylene EPE (pearl cotton), expanded polypropylene EPP (Napron), ethylene vinyl acetate EVA (shoe sole material), and several other high-end fiber materials. I will talk about them when I have the opportunity. .