1. The Xinjiang cotton incident is no longer news in the foreign trade circle.

Why is Xinjiang cotton repeatedly targeted? Quite simply, because in the past, the United States was the world’s number one cotton producer.

In recent years, China’s Xinjiang cotton has developed vigorously. More than 20% of the world’s raw cotton comes from China, 80% of which comes from Xinjiang, especially from the Xinjiang Production and Construction Corps. Due to abundant sunshine, the quality of Xinjiang’s long-staple cotton is widely praised.

In the past two decades, China has been the world’s largest cotton producer. At this time, the starting point for foreign countries to boycott Xinjiang cotton is naturally clear.

It seems to be an economic and trade dispute, but in fact it is still fringe politics. However, fight will continue, fight will continue, the rotation of the earth will not stop, and we still have to wear our clothes.

1.1 What are the advantages of long-staple cotton?

Comfort and quality. Long-staple cotton mainly refers to Egyptian cotton and Xinjiang cotton. Compared with ordinary cotton, the main reason is that the fiber is longer. Under the same sunlight conditions, it is one or two weeks longer, has high maturity, long lint, and good hand feel. Different from the mercerization process, long-staple cotton has its own mercerized halo, which is naturally beautiful.

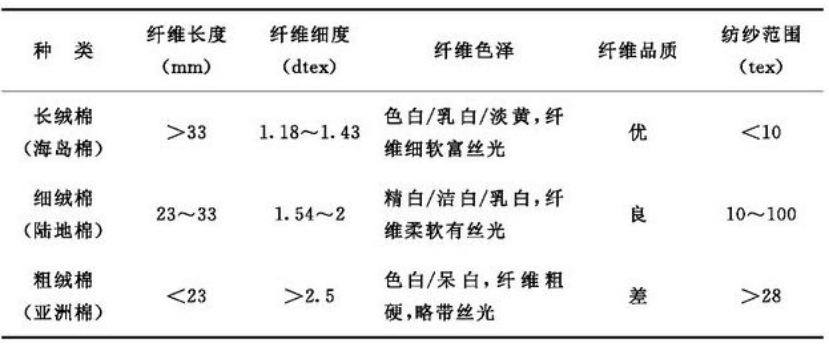

(Thick-staple cotton has basically been eliminated, for reference only)

1.2 What are the differences between different cottons?

“Pure cotton” is not just a concept. According to the national standard, it should be 100% cotton, but in fact, more than 95% (a certain cat) is embarrassed to say pure cotton. Of course, some thick-skinned people dare to say that more than 75% of the products are pure cotton, or 100% cotton.

Xinjiang long-staple cotton is basically the best cotton in China (you must know that China is currently the largest cotton producer in the world), and Pima cotton (PIMA cotton) is the best specialty The general name for velvet cotton, with extremely low output. Egyptian cotton is basically the first choice for customized fabrics for international brands, but after all, the output is limited. The global supply chains of major brands naturally turn to Xinjiang long-staple cotton.

2. Points and lines form a surface, on the importance of yarn

Cotton must be spun before weaving. The difference between combed yarn and carded yarn is that no matter what grade of cotton, “fine” is always better than “common”. The thickness of the yarn and the density of the fabric are important indicators that determine the quality of the fabric.

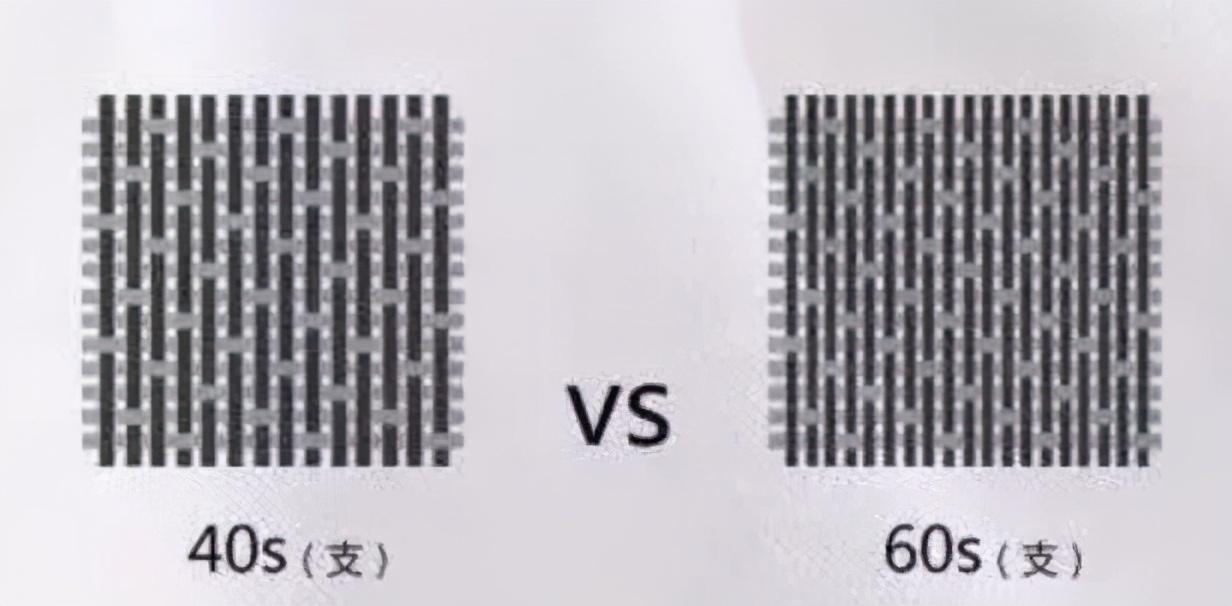

Yarn weaving refers to the thickness of the yarn. The higher the count, the finer the yarn, and the higher the requirements for raw materials. If you don’t believe it, try using hemp rope spinning.

2.1 The higher the quality of the yarn, the better. You can refer to the density and value of gold and iron. Generally, fabrics with a count of 60 or more are considered high-count fabrics.

From a printing perspective, inkjet printing on high-count fabrics has a high degree of precision and strong image detail expression. That is to say, the so-called image resolution and resolution can be higher.

To put it simply, under a microscope, high-count fabrics can carry more effective ink per unit area. One ink droplet has one coordinate, and it will not deviate, which will affect the printing image. Greater accuracy. The effectiveness of inkjet printing on lower-count fabrics may need to be discounted, which will affect the picture effect to some extent.

2.2 Density refers to the number of yarns per unit length in the warp and weft directions. High count is the prerequisite for high density. The higher the yarn weave, the higher the fabric can be woven.

Of course, everything has a critical point. If the density is too high, it will no longer be breathable, so it has the function of windproof and waterproof.

From a printing perspective, inkjet provides stable coloring on high-density fabrics and precise ink volume control. It effectively improves the use efficiency of ink, can more effectively enhance the color details of the image within the unit amount of ink, and greatly reduces the loss of ink from the gaps in the fabric.

More generally speaking, under a microscope, fabric can be said to be the layer of ground (yarn) and river (void) , there is a heavy snowfall (the inkjet process), the ground is completely white, but the river is still clear, and the entire land is full of ravines. It is not until the snow is heavy enough (the amount of ink is large enough) that the entire ground river will be unified. The density determines how much snow falls and whether it can cover the ground evenly.

3. Can mercerized, Lycra and silicone oil be used?

Many times I get feedback from designers about whether it can be printed and whether the color will fade. To put it responsibly, when you don’t see the patient,��It is difficult to determine whether this patient can be cured, not to mention that there may be nothing wrong with him.

3.1 The most encountered problem is actually silicone oil, which is a commonly used softener and a textile auxiliary added to enhance consumer comfort. This is a huge challenge to the color fastness of secondary printing (whether offset printing or direct printing). The heavier the silicone oil, the worse the color fastness. When mass production of fabrics, it is recommended to use hydrophilic softeners. As for whether fabrics containing silicone oil must not be printed, this is actually a matter of quantity and quality. Welcome to discuss in depth.

(For example, do not print on fabrics like the one shown above that cannot seep water)

3.2 The mercerizing (non-mercerized cotton) process is the post-finishing step of alkaline singeing treatment. Alkali particles remaining on the fabric may cause secondary contamination of the pre-treatment liquid (fixing agent), causing the fabric to turn yellow and cause local color abnormalities. In the same way, if the broken velvet of the cut piece remains on the fabric, it will also cause white spots and other defective products to appear after printing.

3.3 Lycra (with different proportions of spandex) cotton belt elasticity is widely praised, but due to inconsistent weaving raw materials (cotton and chemical fiber blends), the dyeing agent at different temperatures The reaction is also inconsistent. Dark dyes in blended fabrics may be free, and quantitative changes lead to qualitative changes. Different proportions of blended fabrics will have different color performance differences in practical applications. Generally, about 5% Lycra cotton is not a big problem. In the same way, modal fabrics have excessive elasticity and serious deformation, so designers with high image quality requirements should use them with caution.