Composite fiber is two or more polymer melts, which are divided by a special distribution plate and extruded through the same spinneret.

There are hundreds of varieties of composite fibers, and there are many classification methods. According to the production method, they can be divided into composite spinning and blended spinning. According to the spinning form There are 5 commonly used types: co-spinning type, side-by-side type, sheath-core type, split type, and island type.

Polyester/nylon composite fiber, which not only has the advantages of nylon’s wear resistance, high strength, easy dyeing, and moisture absorption, but also has polyester’s good elasticity and durability. It has the advantages of good shape, stiffness and no ironing.

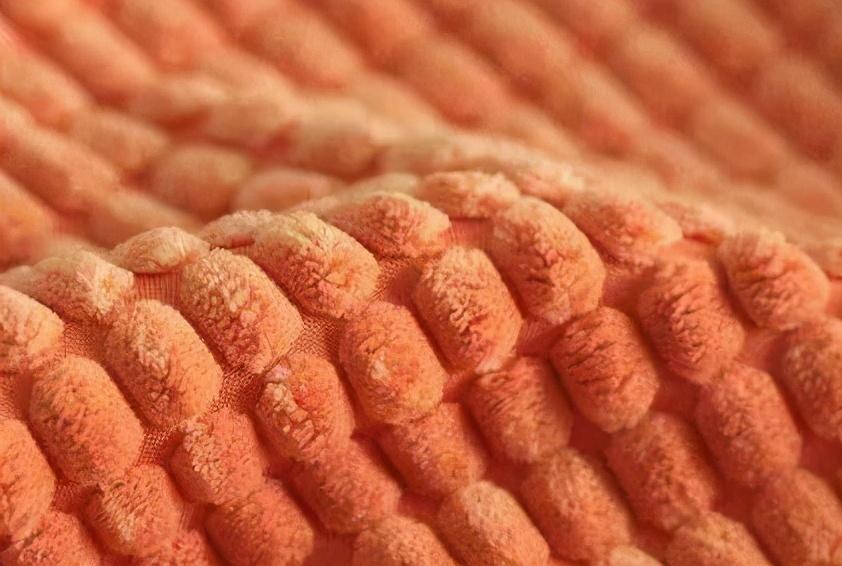

Generally, composite spinning is mainly composed of polyester and nylon, with orange-shaped, rice-shaped and other special-shaped cross-sections. It has good hygroscopicity and is mainly used in cleaning products. , home textile products, etc.

In addition, the low melting point, flame retardant, antistatic and conductive functions of many fibers are also achieved through the special structure of composite spinning.

Polyester-nylon composite microfiber takes advantage of the chemical structural differences between PET and PA, as well as the weak interfacial bonding force and the ability to separate from each other. , which is melt-spun at a certain ratio during the production process.

Usually, antibacterial microfibers add antibacterial agents to chemical fibers in the form of blends or masterbatch additions to obtain durable antibacterial effects.

Compared with antibacterial finishing technology, antibacterial fiber has good antibacterial effect and is durable. The fabric weaving, dyeing and finishing processes are simple, the fiber does not adhere to resin, and the finished fabric feels better. good.

However, this method is highly technical and difficult, especially requiring high antibacterial agents. In addition, most organic antibacterial agents are not resistant to high temperatures and are difficult to use in melt spinning.

Inorganic antibacterial agents, such as antibacterial phosphates, glass, ceramics, oxides, etc., have unique high temperature resistance properties. They mainly contain The antibacterial effect of silver, copper, zinc and other metal ions can achieve antibacterial and deodorizing effects.

Relevant domestic companies have applied antibacterial agents containing a mixture of silver-containing inorganic phosphates and metal oxides to the production of polyester-nylon composite microfibers, using The production technology of blending antibacterial masterbatch and fiber chips to produce antibacterial polyester-nylon composite microfibers and antibacterial fabrics.

In addition, for polyester and nylon composite filament antibacterial microfibers, the specific surface area of the single fiber is not only large. Moreover, the difference is also very large, which makes it easier to cause differences in dyeing speed, and the result is easy to dye flowers.

Therefore, controlling the dyeing rate is one of the keys to dyeing microfibers with disperse dyes. When no leveling agent is added, the dyeing curves of different disperse dyes are quite different, resulting in dyeing flowers and color differences during dyeing. If the transfer effect of disperse dyes is not obvious, these defects will not be overcome.

After adding leveling agent, the dyeing curves of different disperse dyes can be closer. This is very important when dyeing in color combinations.

Researchers have found that an important way for leveling agents to improve the dyeing performance of microfibers is by improving the dyeing curve of disperse dyes and reducing the absorption of different disperse dyes. Differences between dyeing curves, thereby improving the compatibility between dyes. This is very important for color matching dyeing, because when the dyeing rate of disperse dyes used for color matching becomes basically the same, it can ensure the same color gradient, reduce the chance of color difference, and the dyeing reproducibility will be better.

The antibacterial materials use inorganic antibacterial agents (a mixture of phosphate and metal oxide containing 3% silver, average particle size 400nm), spinning grade resin The slices are made of domestic ultra-fine denier nylon slices and domestic ultra-fine denier polyester slices.

The melt spinning method uses the masterbatch addition method to produce melt-spun antibacterial polyester-nylon (80/20) composite ultrafine fibers. Antibacterial masterbatch is added to the polyester component at a proportion of about 2% of the base material.

The process route adopts composite fiber high-speed spinning technology and applies the POY-DTY two-step process to produce fibers with good physical and mechanical properties. The average single fiber of the fiber produced by this method is about 0.2dtex, which is equivalent to 1/5-1/10 of real silk. It can give the fabric good physical and chemical properties and has been promoted and applied in the textile cleaning products and clothing industries.

In recent years, the polyester and nylon composite yarn industry has experienced excessive expansion of production capacity, a reversal of the supply and demand relationship, and certain changes in market conditions. However, with the increase in downstream efforts to develop new products, polyester and nylon composite yarns still have certain advantages. There is room for development. For example, polyester-nylon-cotton composite fabric can not only be used to make men’s and women’s jackets, but also windbreakers. It can be said to be a marketable fabric in winter.

Polyester-nylon composite microfiber can develop its added value. For example, transfer printing of microfiber fabrics can overcome coloring problems caused by the extremely large surface area of the fabric. It has a high authenticity rate and a high dye transfer rate, and its color fastness to washing can reach level 3.

However, from the perspective of wrinkle recovery of microfibers, when the single fiber is miniaturized beyond a certain limit, it will have a negative impact.

As the single fiber becomes thinner, the comprehensive mechanical properties of the fiber also change. Therefore, when considering the miniaturization of the single fiber, a comprehensive balance must be made to ensure the maximum feel. degree of improvement, so as not to lose sight of the other. When the separation degree of polyester-nylon ultra-fine denier composite yarn in the fabric is high, the fabric will feel soft, otherwise the fabric will feel rough.

Due to the differences in the properties of polyester and nylon, targeted post-processing techniques need to be developed. This is also a prerequisite for the wide application of ultra-fine polyester and nylon composite yarns.