Quilts are the quilt category with the highest acceptance by the public

The largest The advantage is that it has balanced performance, which is excellent in keeping warm, fluffy and skin-friendly.

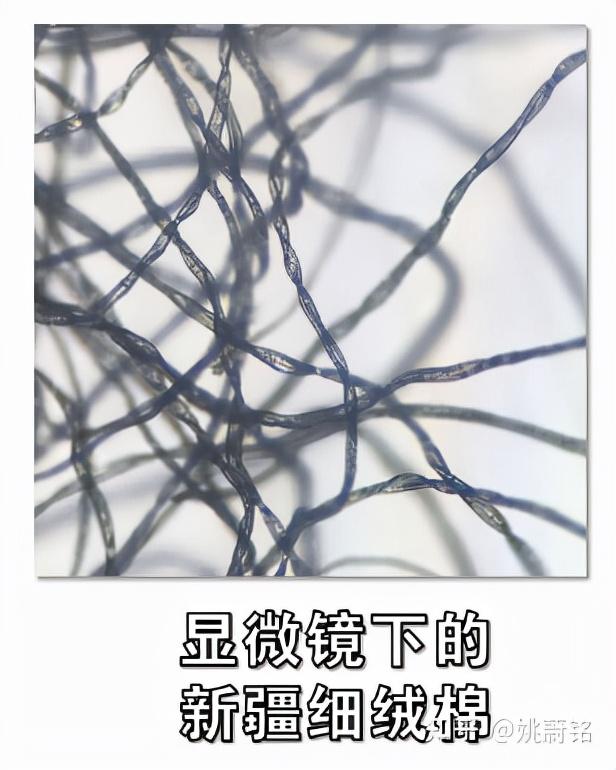

Good fluffiness: Thanks to the natural spiral curl of cotton fiber, it is a natural spring, which is The source of cotton’s bulk.

·Good warmth retention: Cotton fiber is not solid, but has a hollow cell cavity (waist round), which can store large amounts of air, which is a poor conductor of heatThis is the core of cotton warmth. This is why polyester quilts imitate the shape of cotton and also use hollow structures.

Cotton fiber cross-section

Good skin-friendliness: Cotton itself is natural Fiber has good compatibility with biology, and the chemical composition of cotton is cellulose, which contains a large number of hydrophilic groups hydroxyl-OH and carboxyl-COOH. People also have to metabolize while sleeping. The “sweat vapor” secreted by the skin can be well absorbed by cotton.

However, with the sudden rise of down quilts and chemical fiber quilts in recent years, many consumers no longer favor cotton quilts.

Mainly, there are many problems with traditional cotton quilts

· In places or seasons with particularly humid climate, cotton sometimes absorbs moisture due to its good hygroscopicity. Without the moisture in the natural environment,the warmth retention is not as good as when it is dry.

· Low-quality and inferior cotton fibers will harden, agglomerate, and shed after being used for a period of time due to their short fiber length , the cotton needs to be bounced back to become more fluffy. (This is also the reason why there is a profession of playing cotton)

This is a common shortcoming of traditional quilts, but it does not mean that high-quality quilts will have this Case.

Why are traditional quilts used? Not soft enough, elastic enough, or even hardened after a period of time?

The core reason is that there is a problem with the quality of the cotton filling.

1) You must choose Xinjiang cotton, but you cannot blindly choose long-staple cotton:

Because the quality of Xinjiang cotton is world-class (uniquely natural conditions), there is no need to be superstitious about the more famous Egyptian cotton and American pima cotton.

However, I do not recommend choosing the most famous Xinjiang long-staple cotton (cotton fiber length is about 36mm). Instead, you should choose Xinjiang which is slightly shorter in length. Fine-staple cotton (28.0mm is best)

Using long-staple cotton to make quilts is just to cater to consumers, because as a quilt Said, the experience of using long-staple cotton is not good.

The quality of long-staple cotton spinning and weaving is the best. The longer the cotton fiber, the softer the yarn can be spun, and the less hairiness. Higher quality. But as a quilt core that is woven without spinning,longer fibers are counterproductive.

Excessively long cotton fibers will restrict the elasticity of the cotton itself, causing the bulkiness to decrease. Of course, cotton fibers that are too short are not good for making quilts because they will fall off, become hardened, and collapse. So there is a“threshold” for cotton fiber length.

After scientific analysis, the best critical value for quilt bulkiness is around cotton fiber 28.0mm, which can best reflect Bring out the fluffiness of cotton. This is the core secret of long-lasting fluffy quilts.

Just like hair, hair that is too long or too short will have poor fluffiness.

So when buying quilts, you must not be superstitious about the more famous Egyptian cotton and Pima cotton. They are both “long-staple cotton” varieties. Not suitable for making quilts.

“Long Staple Cotton” and ” “Fine-staple cotton” is two different varieties of cotton, which cannot be distinguished simply by length. Good or bad, just like Yao Ming who is 2.29 meters tall is considered a strong man among humans, a giraffe who is 2.29 meters tall is considered a dwarf.

The most advantageous cotton variety of Xinjiang cotton is“fine velvet cotton”, which is also the most suitable variety for quilts. Xinjiang 90 % of cotton production is “fine lint cotton”.

Although the quality of Xinjiang cotton is world-class, many brands did not like to use it in the past. Because Xinjiang is located deep inland, transportation, processing, and time costs are very high. In order to improve moisture, I prefer to use cotton from India, Brazil, and the United States.

“Cotton quality” is the core of the entire quilt. Dapu’s “Xinjiang Milk Cover Quilt” is very good, but it does not have…��Like other businesses, they just make quilts to cater to consumers. Instead, be realistic and choose 28.0mm fine velvet cotton with the highest fluffiness.

But just using Xinjiang fine velvet cotton is not enough. The processing details are differentIt will also affect the user experience. Many businesses are unwilling to spend this time and cost, but Dapu “Milk Cover Quilt” has also put a lot of effort into the processing details.

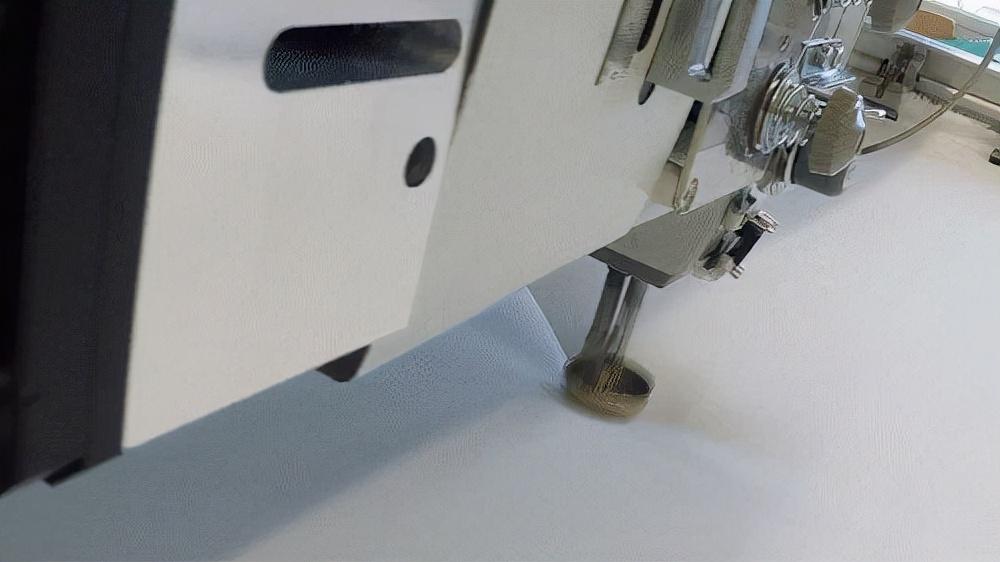

2)Precision quilting (háng) thread

Don’t underestimate this quilting thread, especially if you are a dishonest friend who likes to move around while sleeping. Traditional quilts are easy to lose shape during use, causing one piece to bulge and the other to deflate. This is actually caused by the lack of quilting. (Traditionally, a few simple threads are used to fix the cotton tire, which is very unstable)

Some friends will be very disdainful. Isn’t it just sutures? What’s the technical content?

Indeed, there is really no technical content,but!

It takes time and requires a special quilting machine , these are all potential costs that ordinary merchants can save.

Moreover, the more complex the quilting pattern is, the better the effect of misaligned fixed batting will be, making it less likely to run away, but the higher the time and process costs will be.

A cotton quilt is not cheap but costs several hundred. It should last for at least a few years. You should pay more attention to the details of the product.

3) Thousand-layer cotton laying process

Cotton quilts are not like giving a doll a head It’s like stuffing cotton randomly.

Instead, the rolled cotton is laid out layer by layer, just like building a wall. Into a cotton quilt. With the same thickness, the more and more dense the layers, the better the fluffiness and durability of the quilt.

Thousand-ply quilting, If the traditional quilting technique is hastily passed, the bulkiness will become worse or even harden after being used for a period of time.

When purchasing, you should check whether there is a thousand-layer cotton quilt’ like Dapu’s “Xinjiang Milk Cover Quilt”, so that the quilt can Long-lasting soft, elastic and fluffy.

Among the current quilt products, Dapu’s “Xinjiang Milk Cover Quilt” is made with great care. From the core cotton of the quilt, which uses 28.0mm Xinjiang fine velvet cotton, to the small details of the thousand-layer cotton laying process and quilting threads, everything is done very well.

And I also discovered that Dapu’s “Xinjiang Milk Quilt” still adopts the “Class A Infant Safety Standard”, which can be used by children, the elderly and the whole family as a home textile product , to accompany people for one-third of their day.

Safety, health and purity are the bottom line of home textile products.

No pungent formaldehyde The smell is only a touch of cotton

Even if the “Textile Safety Technical Category” Class B standard is allowed for sale, but for home textile products,I still It is recommended to buy Class A instead of Class B.

Tips for identifying genuine and fake cotton:

Don’t be afraid of buying cotton quilts, be afraid of buying them Low-quality cotton, or even fake cotton quilts.

The cotton itself has a faint yellow color. If it is snow white, it is most likely floor-length bleached cotton. Or back-spun cotton.

Floor surface: It is the leftover material from cotton processing, such as the miscellaneous cotton obtained by combing cotton. ;

Respun cotton: It is loose cotton made from waste clothes that are crushed and bleached in a crusher. The quality of the cotton fibers is particularly poor. To carry germs, refer to the recycled cotton towel incident exposed on March 15, 2020

There are black lumps after burning them, which are low-quality cotton mixed with polyester. Fluffiness, there is no need to do this with a good pure cotton quilt.

There are no black spots on the quilt core. These black spots are actually cottonseed husks. Although there is a process to clean cottonseed husks during the carding process, But no matter how good the machine is, there will still be a small amount of cottonseed hull residue leftand there will inevitably be small black spots.

If it is made into clothes, it will be dissolved and removed with sodium sulfite and alkali solution in the pre-treatment stage of the dyeing factory. But quilts do not go through this process. If they are very, very clean and have no black spots at all, they are definitely respun cotton.

Recycled cotton is a huge market. Otherwise, you would think that the old clothes recycling bin at the door of your community is really set up by a charity. Detailed contact information, address, There are no workplaces.

Most of them are unscrupulous businessmen who borrow well-intentioned old clothes that are not too dirty or torn, simply clean them, package them and sell them by the ton to Africa.

Crush the broken, dirty or blood-stained ones to make recycled cotton. A large part of it is made into quilts, because it is difficult to make clothes when the cotton fibers are broken and too short, but it is the most convenient and easy to make quilts that do not require spinning.

track=”240″>If it is made into clothes, it will be dissolved and removed with sodium sulfite and alkali solution in the pre-treatment stage of the dyeing factory. But quilts do not go through this process. If they are very, very clean and have no black spots at all, they are definitely respun cotton.

Recycled cotton is a huge market. Otherwise, you would think that the old clothes recycling bin at the door of your community is really set up by a charity. Detailed contact information, address, There are no workplaces.

Most of them are unscrupulous businessmen who borrow well-intentioned old clothes that are not too dirty or torn, simply clean them, package them and sell them by the ton to Africa.

Crush the broken, dirty or blood-stained ones to make recycled cotton. A large part of it is made into quilts, because it is difficult to make clothes when the cotton fibers are broken and too short, but it is the most convenient and easy to make quilts that do not require spinning.