Recently, the editor has discovered that many people are confused by the types of cotton yarn. What is a thick yarn? What is recycled cotton yarn? What is the difference between combed yarn and fine count yarn? What kind of yarn is needed to weave flannel? It seems that everyone is really confused.

In fact, there are many types of cotton yarns, including general thickness, spinning method, twist direction, yarn use, and It is divided according to yarn dyeing, finishing and post-processing. There are different division methods to guide and understand cotton yarn. It is much simpler. Follow the editor to learn about it!

Broad classification of cotton yarn

Segmented by general thickness

Generally speaking, we believe that in the public resurgence At this rate, 1 pound of yarn is exactly 840 yards long and is 1 count of yarn, expressed as count (S). According to the count, it can be divided into:

① Thick count yarn: 8-17 count cotton yarn, mainly used for weaving thick or piled and looped cotton fabrics. Such as coarse cloth, flannel, strong cloth, etc.;

② Medium count yarn: 18-27 count cotton yarn is a medium count yarn, used for weaving plain cloth, twill cloth, satin and other general fabrics;

③ Fine count yarn: cotton yarn with count 28-262 and above, used for weaving fine cloth poplin, high-end needles, and woven fabrics.

The softness and fineness of bedding is generally determined according to the count. The larger the branch number, the softer it is.

According to the spinning method

Depending on different spinning methods, combed yarn requires one more combing process than carded yarn, while waste spinning yarn is spun from waste cotton.

① Carded yarn: It is a ring-spun yarn spun by a spinning process without combing process, and is used for general needle and woven fabrics;

p>

(Carded spinning process: cotton distribution → opening and cleaning → carding → drawing → roving → spun yarn → post-processing → finished product inspection.)

② Combed yarn: Using high-quality cotton fiber as raw material, an additional combing process is added during spinning compared to carded yarn. The spun yarn is of excellent quality and is used for weaving. High-end fabrics, such as high-grade poplin, muslin, etc.;

(combed spinning process: cotton distribution→open blowroom→carding→combing→drawing→ Roving → Spun yarn → Post-processing → Finished product inspection.)

③ Waste spinning: refers to all the waste cotton processed in the spinning process as raw material. The yarn is generally only used to weave low-level fabrics such as coarse cotton blankets, terry cloth and packaging cloth;

④ New spinning: It uses a new spinning system Spun yarns, such as compact spinning, siro spinning, serofil spinning, core spun, slub yarn, colored yarn, etc.

According to yarn usage

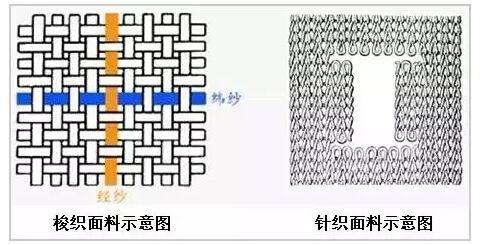

① Warp yarn is a yarn in the direction parallel to the edge of the fabric in woven fabrics. It has greater strength and generally has a greater twist;

② The weft yarn is the yarn in the direction perpendicular to the edge of the woven fabric. The strength requirement is lower than that of the warp yarn, and the twist is generally lower than that of the warp yarn, maintaining a certain degree of softness;

(Twist: refers to the number of turns per inch of cord strength. The strength of the yarn is mainly determined by the twist. Generally, the greater the twist, the greater the strength. )

③ The yarn used for knitting is required to be clean, uniform and with a small twist (twist coefficient less than 330) to prevent breakage during knitting bends;

④ Industrial yarn such as tire cord, conveyor belt yarn, sanitary and medical yarn, etc.

Schematic diagram of warp and weft, schematic diagram of knitted fabric

According to yarn dyeing, finishing and post-processing

① Natural color yarn (also known as original color yarn): maintains the original color of the fiber and is used for weaving original color gray cloth;

② Dyed yarn: original color yarn is made by boiling and dyeing The colored yarn is used for yarn-dyed fabrics;

③ Colored yarn (including mixed color yarn): the yarn is dyed first and then spun. Weaving into fabrics with irregular star dots and patterns;

④ Bleached yarn: made of primary color yarn after refining and bleaching, used for weaving bleached cloth, also It can be interwoven with dyed yarn to form various yarn-dyed products;

⑤ Mercerized yarn: mercerized cotton yarn. There are mercerized bleached and mercerized dyed yarns for weaving high-grade colored fabrics;

⑥ Singed yarn:��The singeing machine burns off the fuzz on the surface of the yarn to make yarn with a smooth surface for weaving high-end products.

Colored spinning

Divided according to spinning principle (or yarn forming equipment)

① Open-end spinning: For example, open-end spinning is the preferred yarn for denim, knitted underwear and many other products, while siro spinning is used to spin some fibers that are prone to hairiness, such as rayon, modal, Tencel, soybean fiber, etc. Its fabric has less hairiness than conventional ring-spun yarn fabrics, is soft to the touch, wear-resistant, and has good breathability.

② Spinning by holding both ends: Ring spinning is suitable for thread making and various products such as weaving and knitting. The tightly woven cloth is breathable. Good, the cloth surface is flat and smooth, making it an ideal yarn for high-end textiles.

There is also a kind of vortex spinning that has become more popular in recent years. This textile technology is improved by using the principle of air gyration. It has strong spinability and is suitable for weaving. Knitted fleece products such as fleece jackets, fleece trousers, scarves, cushions, sofa cloths, furniture cloths and small tablecloths.

Vortex spinning

Split by twist direction

①Backhand twisting (also known as Z twisting) Yarn is the most widely used in various fabrics; ② Hand-twisted (also known as S-twisted) yarn is used to weave the weft yarn of flannel.