In recent years, regenerated cellulose fibers (such as viscose, Modal, Tencel and other fibers ) continue to emerge, meeting people’s needs in a timely manner, and at the same time partially alleviating today’s problems of resource scarcity and natural environment destruction.

Because regenerated cellulose fiber contains natural cellulose The dual performance advantages of fiber and synthetic fibers are being widely used in textiles on an unprecedented scale.

Today we take a look at the most common What are the differences between viscose fiber, modal fiber and lyocell fiber?

01

Ordinary viscose fiber

Viscose (Viscose), the full name of viscose fiber, uses “wood” as the raw material, extracted from natural wood cellulose and Cellulose fibers obtained by reshaping fiber molecules.

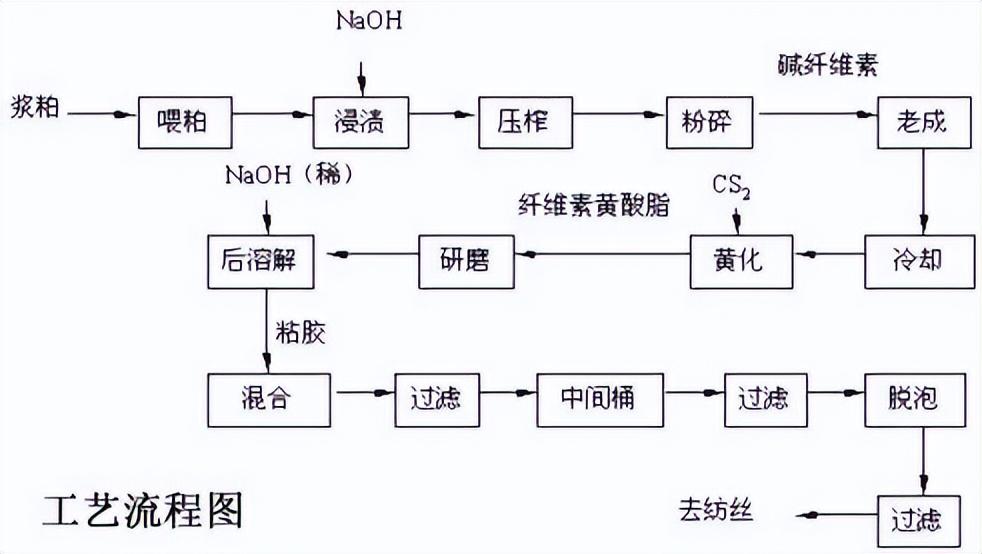

Preparation method

The plant cellulose is alkalized to form alkali cellulose, and then reacts with carbon disulfide to form cellulose xanthate, which is dissolved in dilute alkali solution to obtain a viscous The solution is called viscose, and the viscose becomes viscose fiber after wet spinning and a series of processing procedures.

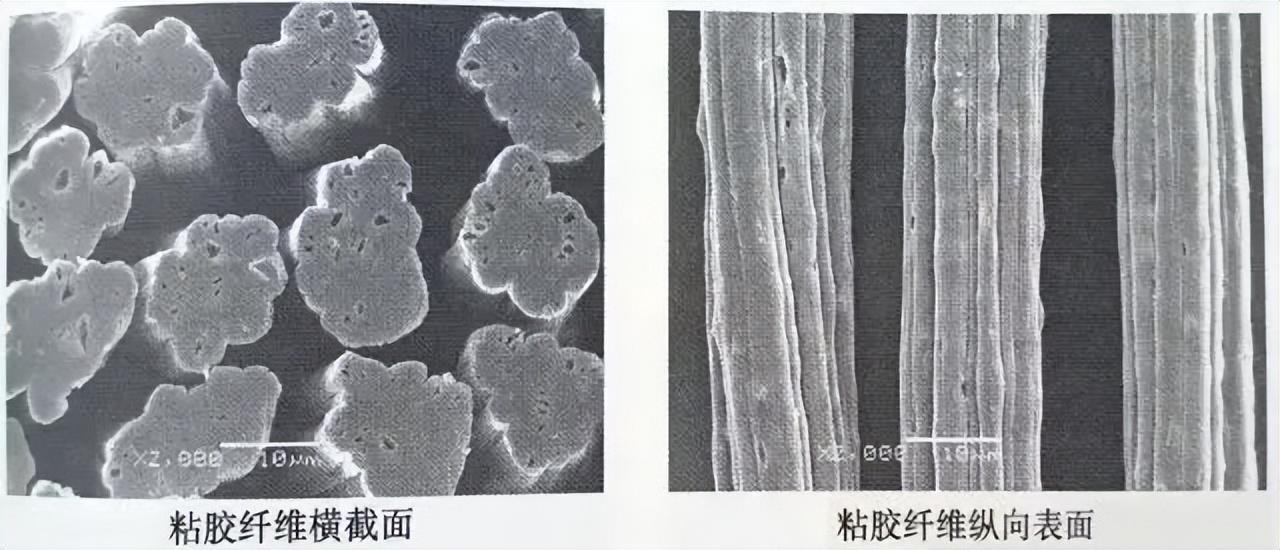

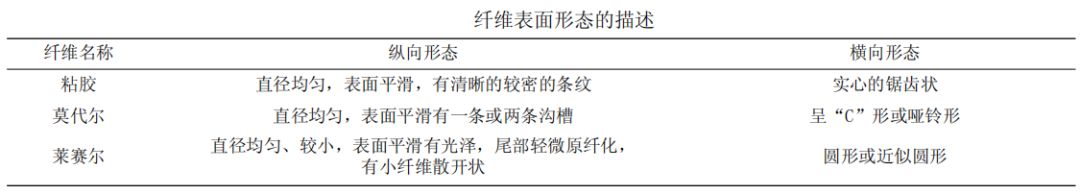

Normal adhesive The inhomogeneity of the complex fiber molding process will cause the cross-section of conventional viscose fibers to be round or irregular, with holes inside and irregular grooves in the longitudinal direction. Viscose has excellent hygroscopicity and dyeability, but its modulus and strength are low, especially the wet strength.

02

Modal fiber

Modal fiber is the trade name of high wet modulus viscose fiber. The difference between it and ordinary viscose fiber is that Modal fiber improves the performance of ordinary viscose fiber. Viscose fiber has the disadvantages of low strength and low modulus in the wet state, but it also has high strength and modulus in the wet state, so it is often called high wet modulus viscose fiber.

Similar products from different fiber manufacturers also have different names, such as Austrian Lenzing Company’s ModalTM brand fiber (Lenzing ModalTM), glass Nosik fiber (Polynosic), Product names such as Fuqiang Fiber, Tiger Kapok and Newal.

Preparation method

The high wet modulus performance is obtained by the special process of the production process. What is different from the general viscose fiber production process is:

(1) Cellulose should have a high average degree of polymerization (about 450).

(2) The prepared spinning solution has a higher concentration.

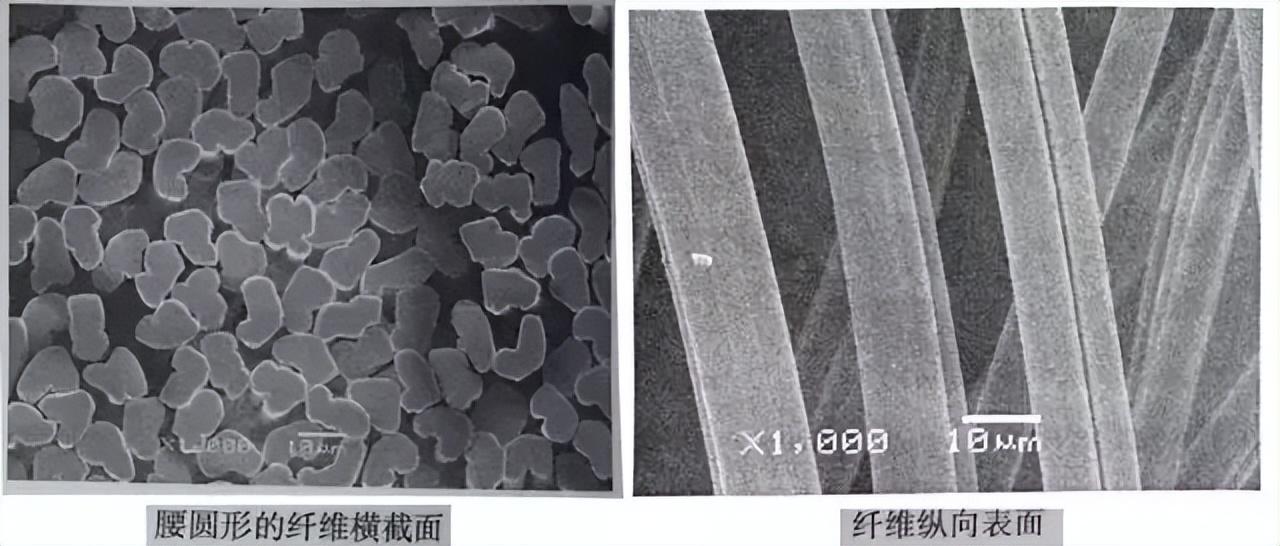

(3) Prepare the appropriate composition of the coagulation bath (such as increasing the content of zinc sulfate), and reduce the temperature of the coagulation bath to slow down the molding speed, which is conducive to obtaining the structure Dense, highly crystalline fibers. The inner and outer layers of the fiber obtained in this way have a relatively uniform structure. The sheath-core structure of the fiber cross-section is not as obvious as that of ordinary viscose fibers. The cross-sectional shape tends to be round or waist-round, and the longitudinal surface is also smooth. The fiber is in the wet state. It has high strength and modulus, and its excellent hygroscopic properties are also suitable for underwear.

The structure of the inner and outer layers of fiber is relatively small It is uniform, and the sheath-core structure of the fiber cross-section is not as obvious as that of ordinary viscose fiber. The cross-sectional shape tends to be round or waist-round, and the longitudinal direction is smoother. It has higher strength and modulus in the wet state, and has excellent hygroscopic properties.

03

Lyocell fiber

Lyocell fiber is made from natural cellulose polymer and is a kind of man-made cellulose fiber. It was invented by the British Cotauer Company and later produced by the Swiss Lenzing Company. The trade name is Tencel. The trade name in my country adopts its homophonic “Tencel”.

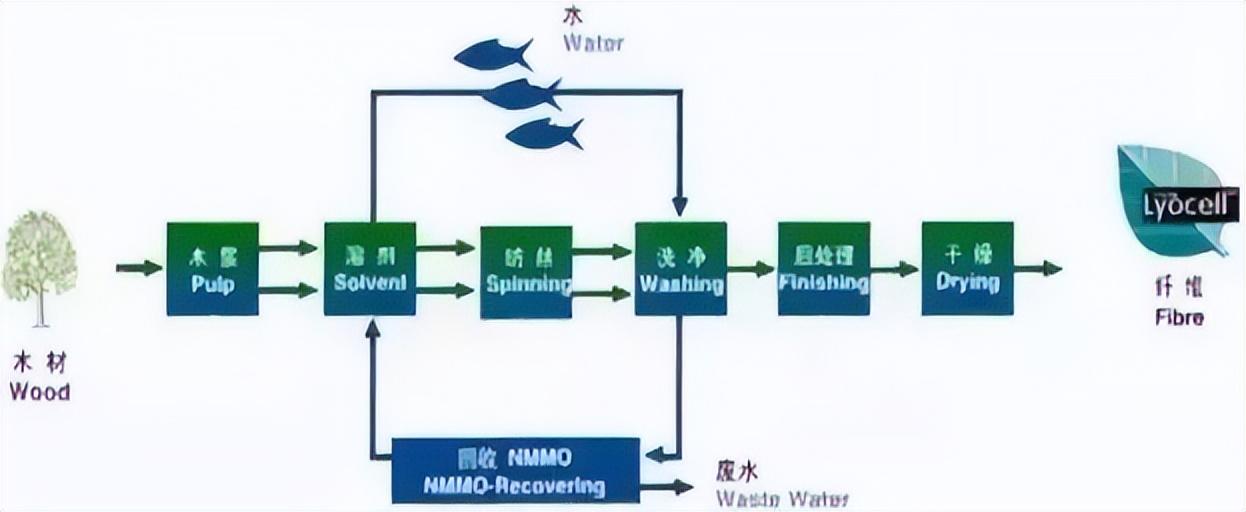

Preparation method

Lyocell uses N-methylmorphine oxide (NMMO) aqueous solution as the solvent. It can directly dissolve cellulose pulp to obtain a spinning solution, and then use wet A method of spinning or dry-wet spinning, using a certain concentration of NMMO-H2O solution as a coagulation bath to shape the fiber, and then stretching, washing, oiling, and drying the spun fibers. New cellulose fibers.

This kind of spinning Compared with the conventional viscose fiber production method, the biggest advantage of the silk method is that NMMO can directly dissolve cellulose pulp, the production process of spinning stock solution can be greatly simplified, and the recovery rate of NMMO can reach more than 99%, and the production process is almost Does not pollute the environment.

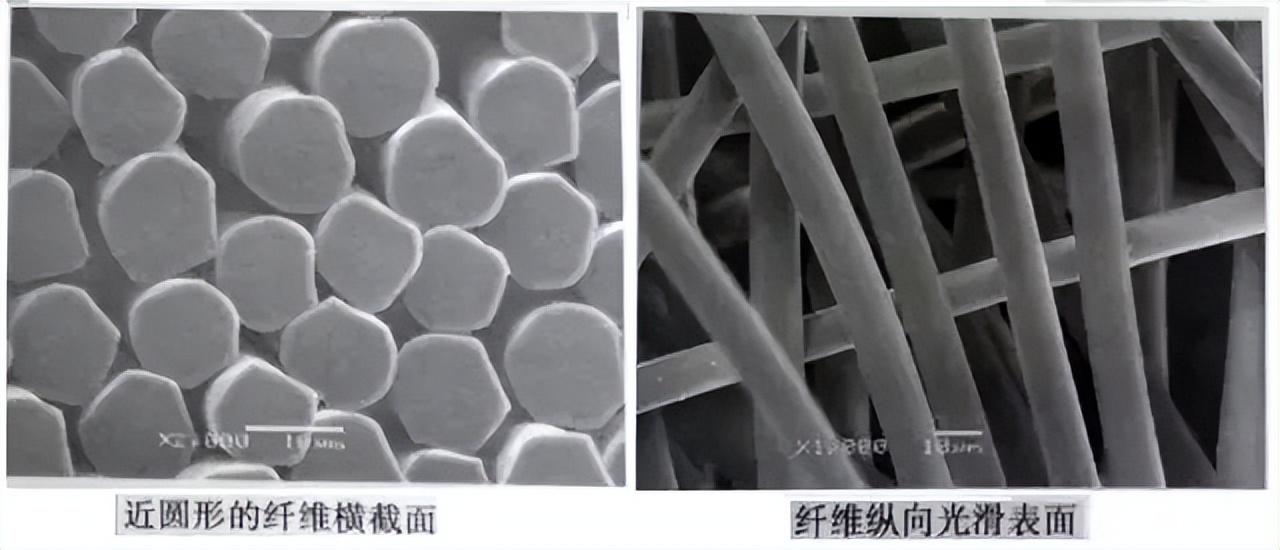

Lyocell fiber morphology and structure are different from ordinary adhesive Viscose is completely different. The cross-sectional structure is uniform and round, and there is no distinction between skin and core layers. The longitudinal surface is smooth and groove-free. It has better mechanical properties than viscose fiber and good dimensional stability in water washing (shrinkage is only 2 %), has high hygroscopicity. Beautiful luster, soft hand feel, good drape, and good elegance.

Viscose, Modal The difference between , Lyocell

1Fiber cross-section

2Fiber Characteristics

- Viscose fiber

It has good hygroscopicity and meets the physiological requirements of human skin. The fabric is soft, smooth, has good air permeability, is not prone to static electricity, is UV-resistant, comfortable and easy to wear. Dyeing, after dyeing, the color is bright, the color fastness is good, and it has good spinnability. The wet modulus is low, the shrinkage is high and it is easy to deform. It feels hard after being put into water, and has poor elasticity and wear resistance.

- Modal fiber

Soft touch, smooth, bright color, color fast It has good strength, the fabric feels particularly smooth, the cloth surface is bright and shiny, and its drape is better than the existing cotton, polyester, and viscose fiber. It has the strength and toughness of synthetic fibers, has a silk-like luster and feel, and its fabric is anti-wrinkle. It has good water absorption and air permeability, but its fabric has poor stiffness.

- Lyocell fiber

With many natural fibers and synthetic fibers Excellent performance, natural luster, smooth feel, high strength, basically no shrinkage, good moisture and air permeability, soft, comfortable, smooth and cool, good drape, durable and durable.

3Scope of application

- Viscose fiber

Short fiber It can be spun purely or blended with other textile fibers. It is suitable for making underwear, outerwear and various decorative items. The filament fabric is light and thin. In addition to being suitable for clothing, it can also be used to weave quilts and decorative fabrics.

- Modal fiber

Modal’s knitted fabrics are mainly used to make underwear. Also used in sportswear, casual wear, shirts, high-end ready-to-wear fabrics, etc. Blending with other fibers can improve the shortcomings of poor stiffness of pure Modal products

- Lyocell fiber

Covering all fields of textile, whether it is cotton, wool, silk, linen products, or knitting or woven products, we can produce high-quality and high-end products.

t-paddingleft-2″>

Soft touch, smooth, bright color, good color fastness, the fabric feels particularly smooth, and the cloth surface has a bright luster , the drape is better than the existing cotton, polyester, and viscose fiber. It has the strength and toughness of synthetic fibers, has a silk-like luster and feel, and its fabrics are wrinkle-resistant and non-ironing, and have good water absorption and breathability. , but its fabric has poor stiffness.

- Lyocell fiber

Tools Natural fibers and synthetic fibers have many excellent properties, including natural luster, smooth hand feel, high strength, basically no shrinkage, good moisture and air permeability, softness, comfort, smoothness and coolness, good drape, and durability.

3Applicable scope

- Viscose fiber

Short fibers can be spun purely , can also be blended with other textile fibers, suitable for making underwear, outerwear and various decorative items. The filament fabric is light and thin. In addition to being suitable for clothing, it can also be used to weave quilts and decorative fabrics.

- Modal fiber

Modal’s knitted fabrics are mainly used to make underwear. Also used in sportswear, casual wear, shirts, high-end ready-to-wear fabrics, etc. Blending with other fibers can improve the shortcomings of poor stiffness of pure Modal products

- Lyocell fiber

Covering all fields of textile, whether it is cotton, wool, silk, linen products, or knitting or woven products, we can produce high-quality and high-end products.