Textile materials differentiated fiber textile materials and natural textile materials

1. New chemical fiber textile materials

1. Tencel fiber

It uses natural wood pulp, dissolves the wood pulp in ammonium oxide solvent and directly spins it, which is completely completed under physical action. Ammonium oxide solvent can be recycled, with a recovery rate of more than 99%. It is non-toxic and pollution-free. It is a new type of cellulose solvent. In addition to the properties of natural fibers and viscose fibers, Tencel fiber also has the characteristics of high strength and good drape. Products made through pure spinning, blending, and interweaving have elegant texture, breathability, soft luster, and are widely used as high-end fashion fabrics. Because it does not emit toxic substances during the production process, Tencel products can be biochemically dissolved after use and will not cause pollution to the environment, so it is known as “green” fiber.

2. Sea Island Fiber

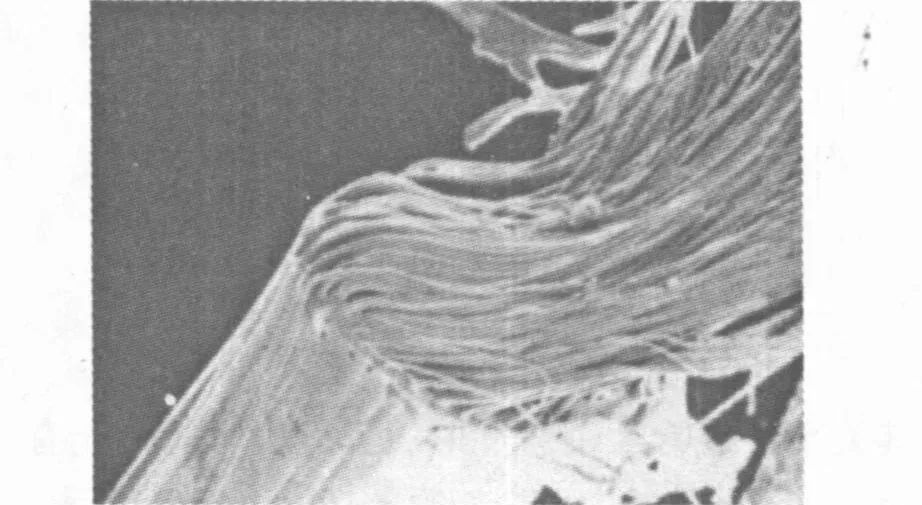

Sea Island Fiber is a member of the ultra-fine denier family. Sea-island type fiber is an ultra-fine or ultra-fine fiber produced by composite spinning technology. The fiber is compounded of island-type ultra-fine fiber and high-shrinkage original filament. Since the ultra-fine fiber effect on its surface is maximized, it can be more Excellent performance of artificial leather. Magic velvet produced with island silk has high softness, good elasticity, antibacterial and mildew resistance, and strong breathability. It is an anti-wrinkle leather fabric and is suitable for men’s and women’s tops, windbreakers, vests, women’s skirts and other clothing; it can also be used Used to make bags, shoes, curtains, sofa covers, car covers, etc.; use suede as a wiping cloth to wipe aircraft, precision instruments, computers, glass products, etc.

3. Modal fiber

Modal fiber is made from camphor wood pulp. The production of pulp and fiber is carried out without pollution to the environment. It is a kind of cellulose fiber with high strength and high moisture coefficient. Its advantage is that it combines the texture of natural fibers with the practicality of man-made fibers. It has the softness of cotton, the luster of silk, and the smoothness of linen. Its water absorption and breathability are better than cotton. At the same time, it can be used in traditional dyeing and finishing equipment. for processing. Has a higher dye uptake rate. The fabric produced has good drape and dimensional stability, and can still maintain bright colors after being washed many times. It is mainly used as a high-end fashion fabric. Modal fiber is obtained from nature, and then can be returned to nature through natural biodegradation, which fully reflects its green and environmentally friendly regeneration characteristics.

4. Acetate

The main raw material is natural wood pulp, which is made from extracted and purified cellulose. It is a semi-synthetic fiber. Its characteristics reflect the style of natural fibers and the functions of synthetic fibers. It has good dimensional stability and silk-like texture.imges.zaomingfu.com/uploads/allimg/20230322/1-2303221TA13R.jpg” style=”height: auto;”/>

The colorful sheep wool that has appeared in the world in recent years is caused by scientists feeding sheep certain metal trace elements to change the color of the wool. For example, feeding iron can Turning sheep wool into light red. Now we have bred colorful wool sheep with bright red, sky blue, golden yellow and brown wool.

4. Colorful rabbit fur

In recent years, an environmentally friendly new member of the rabbit breed has appeared – the colorful rabbit. Raising rabbits Countries with more developed industries have successively raised this kind of colorful rabbits that everyone loves. The United States has many varieties of colorful rabbits. There are a certain number and varieties of them in our country.

5. Optim fiber

Optim fiber is developed by using wool physical modification technology to adjust the internal structure of wool fiber. Its technical principle is to use physical principles to draw and stretch ordinary wool under specific conditions, thereby reducing the fiber fineness by 3 microns. In this way, the fineness of the processed wool will reach or even exceed that of cashmere, and its length can be 3 to 4 times that of cashmere, becoming a brand-new new fiber with cashmere characteristics. With the increasing living standards of consumers, the demand for cashmere in domestic and foreign markets is increasing. However, cashmere goats have obvious destructive effects on vegetation and the ecological environment. They cannot be raised in large quantities, and cashmere resources are difficult to expand. The development of Optim fiber products with cashmere characteristics is in line with the utilization of wool resources, increasing the added value of wool products, and human health concepts of protecting the ecological environment. Products produced with Optim fiber have the characteristics of cashmere: thin, light and soft, smooth to the touch, bright in color, moisture absorbent and warm, high-end in style, comfortable to wear, and have excellent slipperiness, elongation, strength coefficient and other indicators. Better than cashmere.