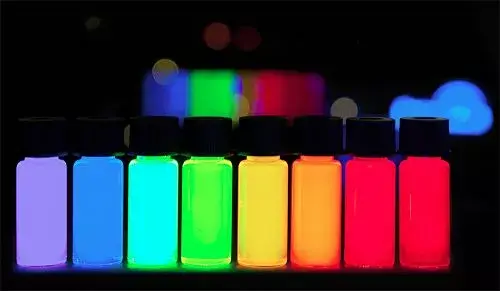

With the vigorous development of the national economy and the improvement of national production levels, consumers’ recognition of the richness and brightness of textiles’ colors continues to expand, and demand is rising day by day. With the characteristics of high emission intensity, bright colors and strong fluorescence, fluorescent dyes are widely used in the dyeing and printing of fabrics in addition to the clothing of traffic police and road maintenance personnel to meet the daily needs of consumers.

Fluorescent dye

Fluorescent dyes: dyes that absorb strongly in the visible range and radiate fluorescence.

The fluorescence reflectance of fluorescent dyes on fabrics depends on the intensity of the ultraviolet light source and the fluorescent substances dyed on the fabrics. The amount of fluorescent material and the fluorescence quantum efficiency. Different fluorescent dyes have different fluorescence quantum efficiencies and different dyeing dosages. Generally, the concentration of fluorescent dye dyeing is around medium color, not too dark and not too light. When the fluorescent dye solution is dilute, the fluorescence intensity is proportional to the concentration. If the solution concentration is too high, the fluorescent substance will undergo a “self-extinguishing” reaction and the fluorescence intensity will decrease. The concentration of the solution is too small, the fluorescence is not obvious, and the brightness is not enough.

Different fabrics cause fluorescent dyes to exhibit different fluorescent properties. For example, when dyed with dispersed fluorescent yellow 8GFF, polyester, acid ester fiber, and cotton fiber show bright fluorescent yellow with green light, but when dyeing acrylic fiber, they will appear bright yellow light, less green light, and no fluorescence.

PH value has an impact on fluorescence reflectance. Generally speaking, dyeing in acidic and weakly acidic dye baths (pH value between 4-6) is beneficial to improving fluorescence reflectivity. Adding fluorescent additives to fluorescent dyes helps to increase the fluorescence reflectance; when fluorescent dyes and non-fluorescent dyes are mixed, the fluorescence reflectance decreases, the proportion of non-fluorescent dyes increases, and the fluorescence reflectance decreases rapidly.

Fluorescent pigments have heterocyclic rings in their molecular structure. Common ones include azocyanines, xanthenes, coumarins, hemicyanine structures, etc. Fluorescent dyes are mainly yellow, orange and red, such as dispersed fluorescent yellow 10GN, dispersed fluorescent yellow 8GFF, dispersed fluorescent red G, dispersed fluorescent pink BG, dispersed fluorescent pink FBS, dispersed fluorescent orange 2GFL, etc.

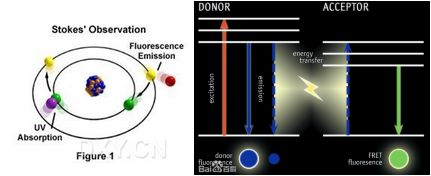

Principle of fluorescence generation

Fluorescence is a photoluminescence phenomenon. When ultraviolet light, or some kind of light, shines on a fluorescent substance, the substance absorbs energy consistent with its characteristic frequency and transitions from the ground state to an excited state with higher energy.

The molecules in the unstable excited state will transfer and relax to the lowest vibration energy level of the excited state in a short period of time, balancing the excited state , and then fall back to the higher vibrational energy level of the ground state. During the fall-back process, the energy is attenuated in the form of fluorescence, and the fluorescence disappears when the irradiation is stopped.

Fluorescent dyes for textiles:

1. Optical brightener

2. Dispersed fluorescent dyes

3. Fluorescent paint

2. If the fluorescent pigment particles are large, the coloring rate will be low, the color will be dim, and the color will be fast. If the density is poor, the color will not be accurate; if the particles are small, the coloring rate will be high and the fastness will be good, but the brightness will be affected.

3. The fluorescent coating is attached to the fiber surface through padding, and then the resin component of the adhesive is used to help the coating fixate on the fiber surface to achieve a certain Color fastness. The fabric will feel stiff due to the influence of the resin contained in the adhesive.

Fluorescent fabric

Fluorescence

Fabric

Fluorescent fabric refers to ordinary fabrics that are fluorescent Fabrics with strong reflective effects after dyeing or coating.

The use of fluorescent fabrics can strongly reflect light to extremely distant targets or targets in the dark, thus serving as a good warning and safety precaution.

The fluorescent fabric is mainly made of chemical fiber, and the fiber is dyed with dispersed fluorescent dyes. It has good color fastness to washing and bright color.

If you want to make fluorescent colors for cotton, linen, silk, and wool fabrics, you basically use fluorescent paint to bond the paint to the fiber through an adhesive. to achieve the purpose of dyeing. The color of fabrics varies due to factors such as surface mechanism, paint concentration, dye uptake rate, and PH value. The fluorescence effect may not even occur, resulting in fluorescent colors having no effect.

Problems and misunderstandings about the use of fluorescent fabrics

Color disadvantages:

1 . The color fastness of fluorescent fabrics to light is very poor.

2. Fluorescent paint has poor color fastness to rubbing and fades badly when washed.

3. The fluorescent colors of fabrics made of cotton, linen, wool, and silk have problems such as difficulty in color accuracy, dim color, and low fluorescence reflectivity.

Production issues:

1. Within the industry The minimum packaging of popular dyes is generally 25 kilograms. Many factories do not prepare fluorescent dyes. If there are multiple colors, the quantity cannot be produced in small quantities.

2. Many natural material fabric factories lack experience in making fluorescent fabrics, resulting in many color fastness and color light problems.

3. Some factories add fluorescent whitening agents to ordinary dyes to pretend to be dyed with fluorescent dyes