Polyester-cotton blended fabric is a variety developed in my country in the early 1960s. The fiber is crisp, smooth, quick-drying, and durable, and is deeply loved by consumers.

Polyester-cotton fabric refers to a fabric blended with polyester fiber and cotton fiber, which not only highlights the style of polyester but also has the advantages of cotton fabric.

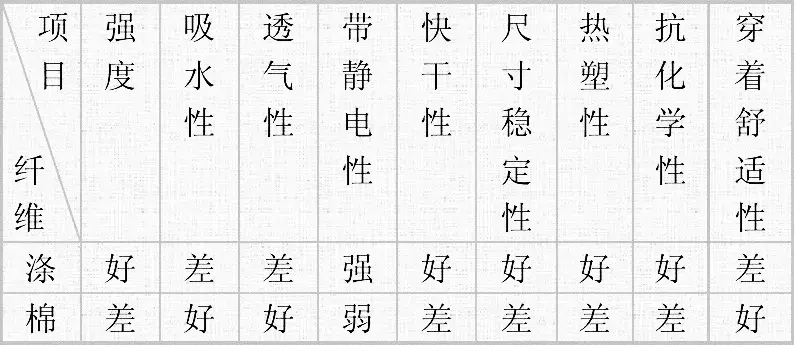

Polyester Performance characteristics of cotton

- Performance characteristics of polyester fiber

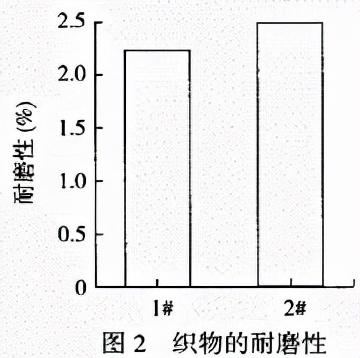

As a new type of differentiated fiber material, polyester fiber has the characteristics of high strength, large modulus, small elongation, and good dimensional stability. The fiber has a soft texture, good cohesion, soft luster, and a certain core warming effect. Polyester has poor hygroscopicity. Under normal atmospheric conditions, the moisture regain is only about 0.4%. Therefore, pure polyester fabrics feel stuffy when worn. However, its fabrics are easy to wash and dry quickly, and have the reputation of “washable and wearable”. Polyester has a higher modulus, second only to hemp fiber, and has excellent elasticity, so the fabric is stiff, wrinkle-resistant, dimensionally stable, and has good shape retention. Polyester has excellent abrasion resistance, second only to nylon, but it is prone to pilling and the pills are not easy to fall off.

- Performance characteristics of cotton fiber

Cotton fiber The cross-section is an irregular waisted circle with a middle cavity; one longitudinal end is a closed tubular cell, which is thicker in the middle and thinner at both ends. The natural curl is a unique morphological feature of cotton fiber. Cotton fiber is resistant to alkali but not acid, and has strong absorbency. The moisture regain rate of cotton fiber under standard conditions is 7% to 8%, and its wet strength is greater than the dry strength ratio of 1.1 to 1.15. Cotton fiber is treated at a high temperature of 10°C for 8 hours without affecting its strength. Cotton fiber decomposes at 150°C and burns at 320°C. Cotton fiber has a low specific resistance and is not prone to static electricity during processing and use.

- Advantages of cotton-polyester blends

It not only highlights the style of polyester and cotton but also has the advantages of cotton fabrics. It has good elasticity and wear resistance in dry and wet conditions, stable size, small shrinkage, and has the characteristics of being tall, not easy to wrinkle, easy to wash, and quick to dry. . Moreover, it has a bright luster, feels smooth, crisp, and has a certain degree of elasticity. The creases are not obvious after being rubbed by hand and it recovers quickly. However, it also inherits the disadvantages of chemical fiber: it is prone to fluffing and balling at friction points. The fabric made of polyester-cotton blend has a thick, soft feel and is more comfortable to wear. It will not deform, wrinkle or shrink after washing.

Let’s take a look at the comparison between polyester-cotton blends and pure cotton:

Note: Fabric (weave is plain weave) specifications: 1# polyester/cotton 50/50 18.3tex×18.3tex×296×228; 2# pure cotton 18.3tex×18.3tex×292×226.

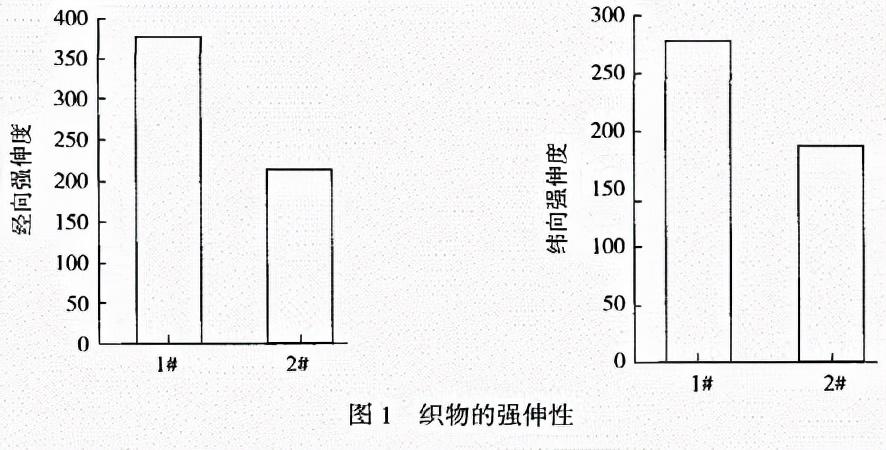

Strength (polyester-cotton blend>pure cotton):Refer to GBT3923.1-2013 “Textile properties of textile fabrics Part 1: Determination of breaking strength and elongation at break)” test, clamp distance 200mm, take 3 pieces in each longitudinal and latitudinal direction for testing.

,

This is the composition of polyester and cotton The main method of proportion and ratio, here are two concepts, the first is to judge the ingredients, and the second is to judge the proportion of ingredients. Obviously judging ingredient proportions is more difficult. Judgment of proportion is achieved through bipolar analysis and comparative analysis.

First of all, let’s look at the burning performance characteristics of all-cotton and all-polyester fabrics. Then, when the polyester-cotton blended fabric in between burns, Various characteristics must be in the middle of the performance characteristics of pure cotton cloth and pure polyester cloth, so as to determine the approximate proportion.

Then the proportion of ingredients is further determined through comparative analysis. That is to say, by comparing and burning a piece of cloth with a known proportion, you can judge the proportion more accurately. The polyester/cotton 65/35 blended fabric we produce and sell has undergone third-party chemical testing and the actual ratio is polyester/cotton 65.5/34.5, which can be used as a comparison reference. The proportion of conventional varieties on the market is mostly polyester/cotton 40/60, 45/55, 65/ 35, 80/20 and other fixed specifications, so it will be easier to judge.

So what characteristics should we observe when burning?

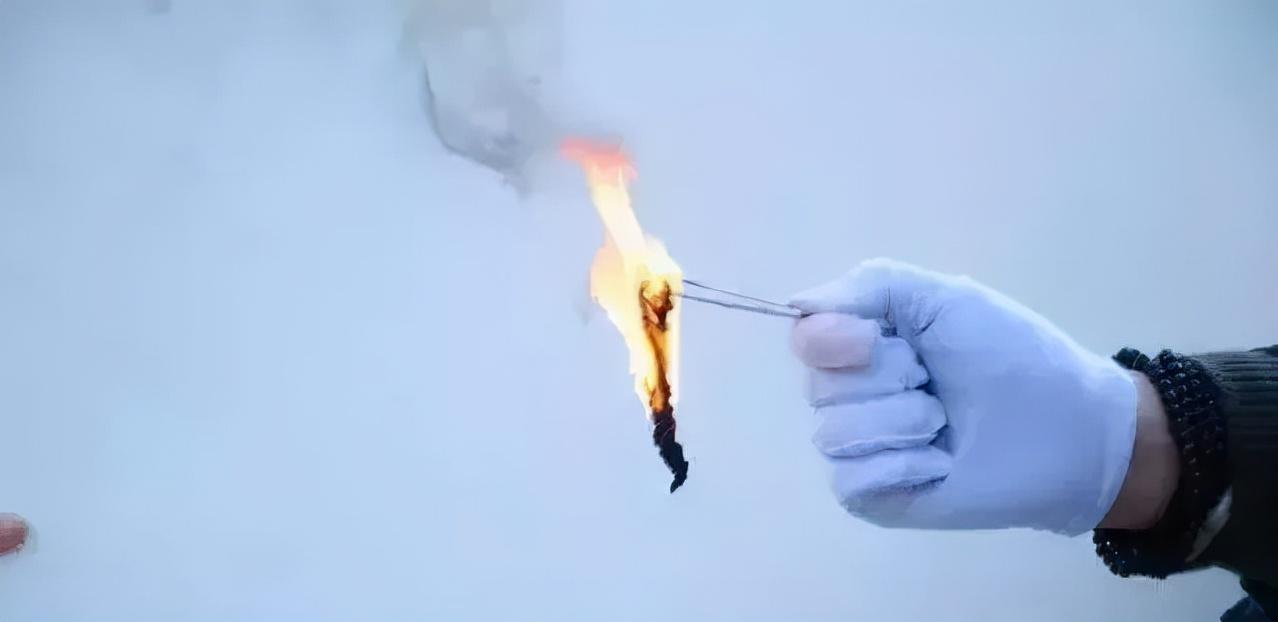

First: Smoke, produced by burning undyed cotton cloth Smoke is green smoke or white smoke, while polyester fabric is black smoke. The polyester-cotton blended fabric is black smoke accompanied by black flying catkins. The higher the polyester content, the blacker the smoke and less flying catkins.

Polyester cotton burns with black smoke

Second: Smell, All cotton cloth smells of burning paper, 100% polyester cloth has a pungent smell of burning glue, and polyester cloth has a pungent smell of burning glue. Cotton blended fabric also has a pungent smell of burning rubber.

Third, burning speed and state, 100% cotton fabric is flammable, and will continue to be accompanied by hidden sparks after being extinguished, 100% polyester fabric is refractory to fire, hot melt will drip fire, and there will be no sparks after extinguishment. Polyester-cotton blended fabric is somewhere in between. The more bright sparks appear during burning, the larger the area. The longer the sparks remain ignited after being extinguished, the more cotton it contains.

Cotton burning

Fourth, combustion residues ,Undyed cotton has gray-white ash, which melts at the touch of a touch, while pure polyester has It is a hard black lump with a smooth surface. Polyester-cotton blended fabric is somewhere in between, with black lumps and an uneven surface. It will break when rolled but will not completely melt. The more polyester it contains, the harder the residue will be and the smoother the surface will be.

Observe the above aspects and compare them with standard polyester-cotton 65/35 or a known ratio to determine the approximate composition ratio.