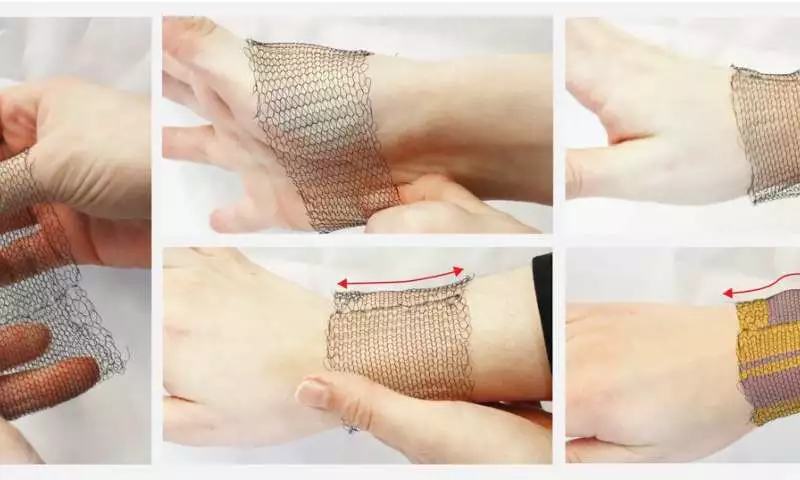

Researchers at the University of Minnesota (Minnesota) in the United States have developed a temperature-sensitive textile fabric that relies solely on human body heat as a power source to move with the movements of various parts of the body. Activities undergo shape changes and adjustments.

The fabric has similar properties to typical knitted fabrics, except that it uses a special material – shape memory alloy (SMA) Made of SMA material that changes its shape when the temperature rises.

This temperature-sensitive fabric can be used to customize different styles of garments. The garments have good shaping properties and can even be bent and fitted in unique ways. to various parts of the body, such as behind the knees. In the future, the fabric can also be made into tights. This tights is loose from the beginning, and after being triggered by the wearer’s body temperature to deform, it can fully fit the body, making it convenient and comfortable.

Professor Brad from the University of Minnesota who led this research

Holschuh said: “This research can create garments that can change shape through physical mechanisms. It also solves the two problems of how to drive fabric deformation without requiring a lot of power or heat and how to make textiles or garments fit various parts of the body. It has taken an important step in the research and development of smart textiles. At the same time, the research results are also of great significance in the fields of medical health, aerospace and commercial applications.”

In addition, the University of Minnesota, in collaboration with NASA, studied the dimensions of the human calf and subsequently designed, manufactured and tested a device that accurately conforms to the shape of the leg and adapts to the spinal muscles. SMA-based knitted garments worn by patients with amyotrophic atrophy.

The team plans to integrate these fabrics into full-size garments in the next step, which can solve various problems of poor fit and improve the comfort of clothing on the body. Fit. At the same time, the fabric can be further applied to medical-grade pressure socks and other products.