Imagine that in the mall, when your partner chooses a T-shirt for you to evaluate, you gently touch the pattern and mutter: “Well, This is a heat transfer process, the pattern is too big and airtight”

Imagine again, when the boss asks you to order employee uniforms, the service provider When you were boasting about your craftsmanship, you asked to the point: “What mesh size do you use for silk screen printing?”

Isn’t that very interesting? Stylish? Isn’t it very interesting? But is it bitter to understand the craftsmanship? Don’t be afraid, let Xiao T use “poetic” language to let you understand the four major craftsmanship of custom-made cultural shirts in seconds!

1. Silk screen printing

Just like sunlight shining through the gaps between leaves

The unobstructed slurry seeps through the fine mesh

Is printed on the clothes

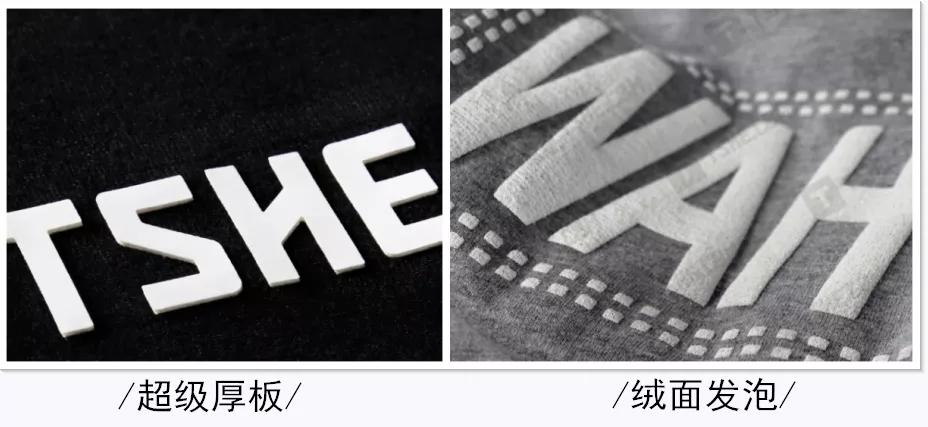

Screen printing is a very common printing process. It first makes the pattern into a screen printing plate, and the pattern part of the printing plate has a mesh to see through the printing material. The mesh of the non-pattern part is impermeable to the printing material, and then the slurry is squeezed onto the clothes through the printing plate, and then dried and shaped.

It can make the printed pattern appear more three-dimensional and refined, and different materials of paste will create different tactile and visual effects.

2. Direct injection process

Recording life with photos Same

The direct-injection process is similar to a printer

Printing likes and attitudes directly and clearly on clothes Top

Clear colors

The production process of direct-injection printing mainly includes drawing, Tinting, printing and fixing. Its process principle is similar to that of a printer. It can print patterns directly on clothing, and is suitable for patterns with rich colors or gradients.

Many people asked Xiaoyi: Isn’t this just like color printing photos?

Having said that, because the object of printing is clothing fabric, the color is a test for the craftsmanship. The color difference needs to be coordinated during drawing and color matching. The color needs to be fixed after printing to make the pattern bright and not easy to fade. .

3. Heat transfer

Just like what I used to do when I was a kid Tattoo stickers

The pattern printed on the heat transfer paper is transferred to the clothes through high temperature

Up

The heat transfer process requires color-printing the printed pattern on transfer paper (a transparent film similar to plastic material), and then using a laser cutting machine to The outline of the pattern is cut out and then placed on the garment, which is then bonded to the garment with heat and pressure through thermal transfer.

The heat transfer process has bright colors and a high degree of color and detail restoration. It is suitable for more colors or gradient patterns. The heat transfer area should not be large.

4. Embroidery

The charm of embroidery is p>

Every stitch and every thread

shows retro and ingenuity

Everyone must be familiar with the embroidery process. It uses needles and threads to pierce colors on the fabric and embroider various patterns.

In the customization process of cultural shirts, common embroidery processes include needle embroidery, tatami embroidery and patch embroidery. Its patterns are exquisite, neat, three-dimensional and tough in texture. It is sturdy and very suitable for logo making and commemorative date embroidery.

Many people think that printing is just printing colors on fabric , as long as the design looks good. In fact, it is not the case. Pattern is a necessary condition, but different printing processes have different effects on the texture of clothes, the display of patterns, and the expression of attitude.