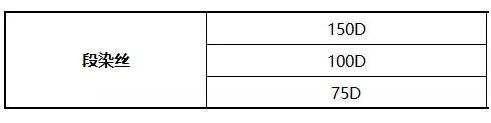

Section dyed yarn

Section dyed yarn adopts imported special yarn dyeing equipment and a unique yarn dyeing process.

The same yarn can be dyed with two or more different colors, thus changing the traditional single-color yarn dyeing style and fabric weaving style .

A fundamental breakthrough has been made, showing the regularity of irregularities, showing a three-dimensional effect on a plane, with rich colors, rich layers, and the largest Design and aesthetic needs are met to a great extent.

Yarns suitable for segmented dyeing are: cotton, polyester cotton, acrylic cotton, viscose staple fiber, acrylic, rayon, polyester filament, pure Plush thread, nylon thread, nylon staple fiber and various blended yarns.

Can be used for segmented dyeing: reactive dyes, acid dyes, disperse dyes, paints, etc.

Diamond wire

Diamond wire is actually a kind of Light flat yarn belongs to the category of straight yarn, usually 50D to 150D, and the color is usually white and black.

Diamond wire belongs to the FDY series, but its gloss is brighter and more lustrous than regular FDY, so it is called diamond wire.

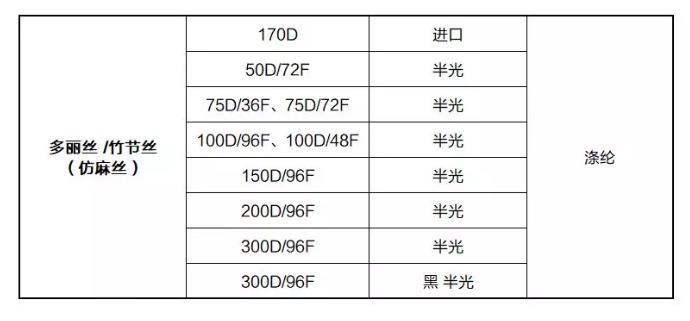

Doris

Doris is a special polyester raw material. Raw material, due to its irregular thick details resembling bamboo knots in appearance.

Doris has the advantages of starch-free weaving, wear-resistant fabric and crisp feel like hemp fiber. Mostly used in women’s knitted fabrics, curtain fabrics, etc.

Advantages of Doris fabric:

1. Strong and durable, wrinkle-free and crisp, Good dimensional stability

2. Poor water absorption, easy to wash and dry, no need to iron

Dolly Disadvantages of silk fabrics:

1. Easy to generate static electricity and prone to pilling

2. Not easy to wear Comfortable

Doris fabric can be used to make trousers, fashionable clothes, casual wear, shirts and other ready-to-wear fabrics!

: center;”>