1. Fabric density

Fabric density refers to the unit length of the fabric in the warp or weft direction. The number of yarns, represented by M, is divided into warp density and weft density. Warp density, also known as warp density, is the number of warp threads per unit length in the weft direction of the fabric; weft density is similarly defined. The warp density and weft density are both measured in “root/10cm”. It is customary to write the warp density and weft density from left to right as “M-XM”, such as 236X220, which means that the warp density of the fabric is

236 threads/10cm, weft density is 220 threads/10cm.

If you need to express the warp and weft yarn density and warp and weft density of the fabric at the same time, you can write them in the following format from left to right:

NtT× NtW× MT×MW

In most fabrics, the warp and weft density configuration is The density is greater than or equal to the weft density.

The warp and weft density of the fabric has a great influence on the performance and appearance style of the fabric. Obviously, if the warp and weft density is high, the fabric will be tight, thick, stiff, strong, and wear-resistant; if the density is low, the fabric will be thin, soft, and breathable. At the same time, the ratio of warp and weft density will also cause significant differences in fabric performance and style, such as plain cloth vs. poplin vs. serge, gabardine vs. khaki, etc.

The warp and weft density can only be used to compare the tightness of fabrics with different densities of the same organization and made of yarns of the same diameter. When the diameters of the yarns are different, there is no comparison.

2. Fabric tightness

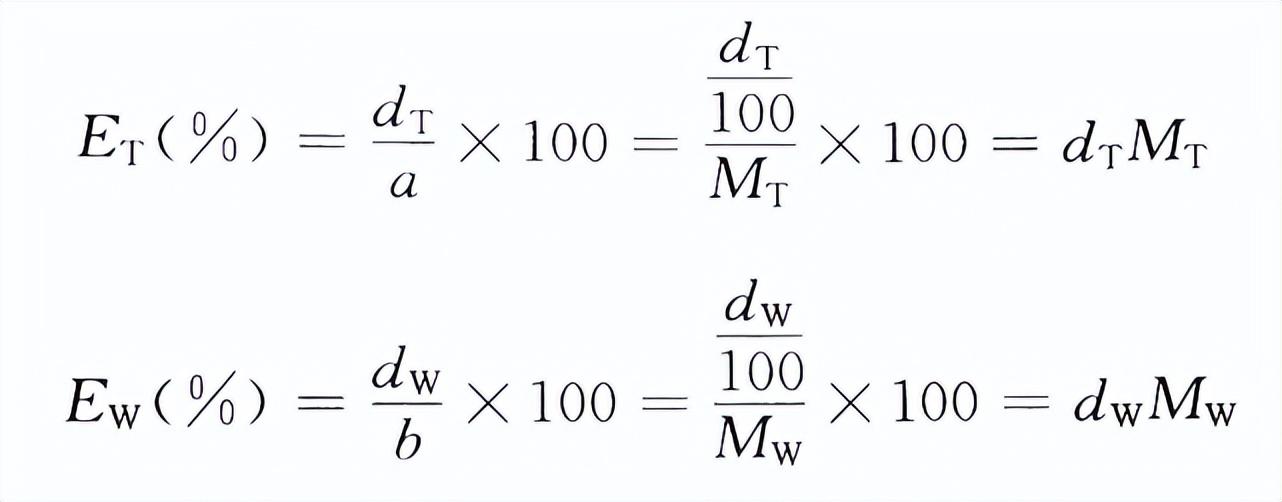

Fabric tightness, also known as coverage coefficient, refers to the ratio of the projected area of the yarn to the area of the fabric, represented by E. There are warp tightness and weft tightness. According to the definition, the calculation formula of longitude and latitudinal tightness can be obtained:

Formula:

ET and EW – warp and weft tightness;

dT and dW – warp and weft diameter (mm);

a and b – center distance of two adjacent yarns (mm);

MT and MW – warp density and weft density (root/10 cm).

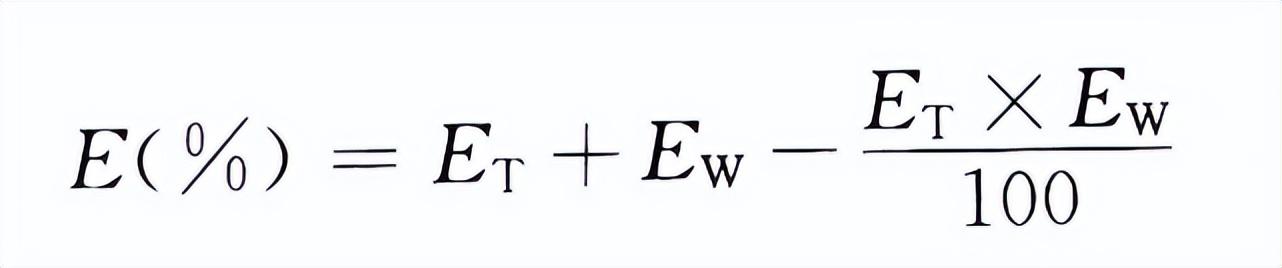

Total tightness of fabric

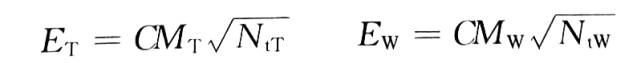

Consider the relationship between yarn diameter and yarn fineness

, then

The diameter coefficients of several yarns are shown in the table below.

Diameter coefficient of yarn

Yarn category diameter coefficient CCotton yarn 0.037 combed wool yarn 0.040 carded wool yarn 0.043 ramie yarn 0.038 silk 0.037 polyester/cotton (65/35) yarn 0.039 polyester/viscose (65/35) yarn 0.039 polyester/nitrile (50/50) yarn 0.041 wool/ Sticky (65/35) woolen yarn 0.041

Various fabrics, even if the raw materials and structures are the same, if the tightness is different, the performance and appearance style will be different. Tests have shown that fabrics that are too tight in the warp and weft directions have increased rigidity, decreased wrinkle resistance, increased flat abrasion resistance, reduced torture resistance, and a hard feel; if the fabric is too tight, the fabric will be too loose and lack body bones. .

In addition, there are certain constraints between the meridional tightness, the weft tightness and the total tightness. Under the condition that the total tightness is certain, when the ratio of warp tightness to weft tightness is 1, the fabric appears the tightest and has the greatest rigidity; when the ratio between the two is greater than 1 or less than 1, the fabric is softer and has good drape. .