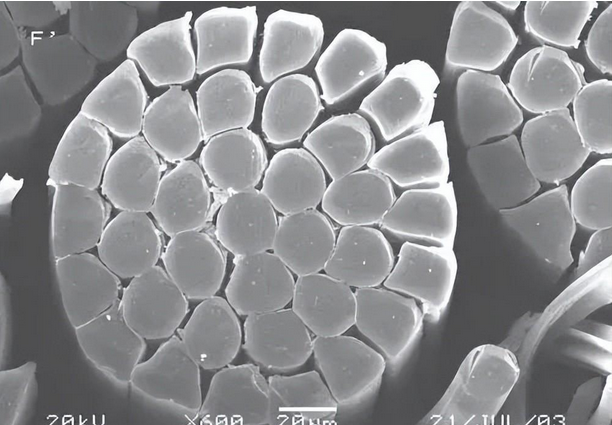

Island fiberIs a major method of making microfibers. It is formed by one polymer embedded in another polymer (marine phase) in a very fine form (island phase). Because the dispersed phase fibrils are in the state of islands in the fiber cross section, and the continuous phase matrix is in the state of the sea, it is vividly called sea island fiber.

Sea-island fiber is also called fibril-matrix composite fiber. Its island phase component is a fibril structure, and its marine phase component is an amorphous structure. In the cross-sectional direction, the components of the fibril structure are embedded in the amorphous structural components, which are distributed like islands. In the longitudinal direction of the fiber, the polymers of the two components are continuously dense and evenly dispersed. From the perspective of the entire fiber, it With the linear density and length of conventional fibers. After dissolving the soluble sea components, ultra-fine fibril bundles are obtained.

There are two commonly used island methods: one is the composite spinning method, the two polymers are melt-spun through a twin-screw composite spinning machine and a special spinneret assembly. One of the polymers has a regular Distributed in another polymer, it can be spun into filaments;The other is Blended spinning method, two polymers are blended and spun into one component (island component) is randomly distributed in another component (sea component) to produce short fibers.

The sea-island method can freely change the sea/island ratio and control the linear density and cross-sectional shape of the fiber. In order to reduce costs, the amount of dissolved components should be minimized, that is, The less the sea component, the better, but a comprehensive balance should be considered so that the solvent has good contact and dissolution conditions for the soluble components.

The island component of sea-island fiber generally uses polyester (PET) or polyamide (PA); the sea component can be polyethylene (PE), Polyamide (PA or PA66), polypropylene (PP), polyvinyl alcohol (PVA), polystyrene (PS), acrylate copolymer or modified polyester, etc.

The number of islands ranges from 16, 36, 64 to 200, and can reach 900 or more. The ratio of sea to islands has changed from the original 60:40 evolved into 20:80, or even 10:90. The popular island-type microfibers currently on the market have polyester as the island component and soluble modified polyester as the sea component. The islands are in the shape of filaments in the fiber, with the number being 24, 36 or 37. The ratio of sea to islands is 20:80. The linear density of the obtained island fiber is generally 0.11~0.0011dtex.