How to identify textile fibers quickly and effectively? This article introduces in detail the identification methods of various types of fibers. Come and learn with the editor!

Visual inspection method of burning and hand feeling

It is a method of identifying fibers by sight and touch. The principle is to rely on human sensory organs to qualitatively identify textile fibers based on the combustion characteristics and appearance, color, gloss, length, thickness, strength, elasticity, feel and impurity content of various fibers. This method can quickly identify various textile raw materials without resorting to instruments and is extremely practical.

Identification of colored cotton and dyed cotton

The difference between colored cotton and dyed cotton mainly depends on the color on the fiber cross-section. If it is colored cotton, the color on the fiber cross-section gradually becomes lighter from the center to the edge of the cross-section, while the dyed cotton fiber cross-section has the darkest color at the edge of the fiber section and the color at the center. The edge gradually becomes lighter, because during the spinning process, while the inner and outer layers of the fiber are transferred, the individual layers of fibers have a significant squeezing effect on the inner layer of fibers.

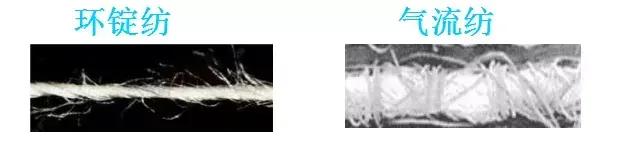

Identification of ring spinning and open-end spinning

Ring spinning is spun on a spinning frame, and the twist direction of the spinning yarn is Z twist, so S twist is used for untwisting, and the fibers can be separated.

Open-end spinning forms a vortex through the swirling air flow, so the fibers on the surface of the yarn are entangled with each other, and the fibers inside have a certain twist. However, because the surface fibers are entangled with each other, it does not matter whether it is solved by z twist or S twist. Twisting cannot separate the fibers.

Therefore, the two can be distinguished by the above method, and for the same yarn count, the strength of ring spinning is better than that of open-end spinning, and the hairiness and evenness of open-end spinning are better than ring spinning.

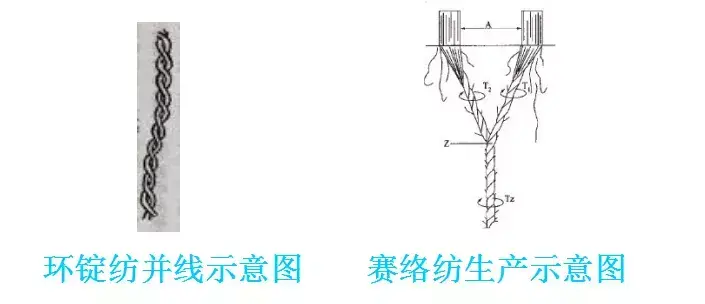

Identification of double-stranded ring spinning yarn and siro spinning

Ring spinning is spun on a spinning frame, and the twist direction of single yarn spinning is Z twist, and the two single yarns are combined with S twist. In Siro spinning, two slivers with a certain distance are fed into the spun yarn drafting area. They are drafted separately and then twisted into yarn. Moreover, the two yarns are “Z” twisted. After twisting into yarn, the twist direction is still “Z”. Z” twist. Therefore, you can distinguish the two by looking at the combined twist direction of the yarn.

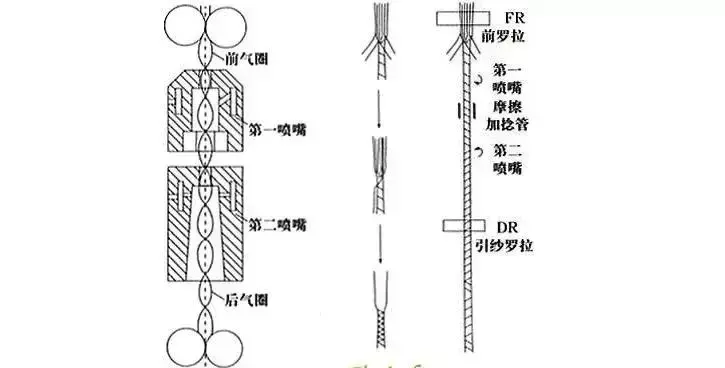

Identification of air-jet spinning and vortex spinning

The structure of air-jet yarn is divided into two parts: yarn core and outer fiber. The yarn core is parallel and twisted, and has a tight structure. The outer fiber is loose and irregularly wrapped around the yarn core. Therefore, the air-jet yarn has a fluffy structure and a fuller appearance. The vortex yarn structure is also divided into yarn core and outer fiber. The core fiber is arranged in parallel and has no twist. The outer fiber is wrapped in a regular spiral on the surface of the yarn core, and the outer layer of regular spiral wrapped fibers has a high proportion, accounting for 60% of the total fibers. %, so that the internal untwisted fibers are almost completely covered, overcoming the problem of core exposure of air-jet yarn, and the surface fiber arrangement is closer to that of traditional ring-spun yarn, with a tighter structure. Therefore, as long as the outer fiber is peeled off and the inner fiber is twisted and the outer wrapped fiber is regular, the two can be distinguished. And air-jet spinning mainly spins chemical fiber and cotton blends, purified fiber yarns and their blended yarns. There is no air-jet spinning for cotton.

Identification of combed yarn and compact spinning yarn

In compact spinning, you can see that there are very few neps in the yarn on the entire cloth surface, the yarn is also very even, and the cloth surface is very smooth. In addition, you can also look at the disassembled yarn. If it is compactly spun, the whole yarn will have very little hairiness, the surface will be smooth, and the strength will be better than combed cotton. The entire cloth surface feels thinner than combed cotton. Therefore, we can distinguish them from the above three aspects.

Identification of compact spinning and siro compact spinning

The similarity between compact spinning and siro spinning is that they both add grilles and air suction condensing devices to the twisting triangle area of traditional ring spinning, so the yarn is even and the strength is increased. , the silk thread has less hairiness. The difference is that in compact spinning, a single yarn is fed to the spinning frame, while in siro spinning, two rovings kept at a certain distance are fed to the spinning frame. After drafting, the two single yarn slivers are output from the front roller, and Due to the transfer of twist, the single yarn strips have a small amount of twist. After being spliced, they are further twisted into a ply-like yarn and wound on the bobbin.

<img src="https://www.garmentmanufacture.com/wp-content/uploads/2023/Uploads/image/20231129/m4mck30ct0c.jpg" data-image_The flame color when nylon burns is light blue, while the flame color when black or dark nylon burns is light yellow.

3. Whether acrylic fiber is drawn yarn or low-elastic yarn, it smells bad when burned, and the color of the flame when burning is light red.

Use this to identify these three fibers.

Identification of cotton yarn from linen cotton and linen viscose yarn

If the cotton yarn is not a slub yarn, whether it is ring spinning or open-end spinning, the whole yarn The evenness of the yarn is basically uniform. Flax spinning is carried out in a semi-degummed condition, and the single fibers of hemp fiber are shorter, so as long as flax is contained in the yarn, no matter what the blending ratio is, the spun yarn will always be uneven. , the longitudinal direction of the yarn shows irregular bamboo sections with different thicknesses, and the spacing between the bamboo sections is also irregular. So as long as we start from this characteristic, we can distinguish them.

Identification of rayon yarn, modal and tencel

Using that the wet strength is much smaller than the dry strength, you can easily distinguish rayon yarn from modal and tencel. Silk is completely different. Modal and Tencel mainly look at the fibrillation phenomenon on the surface of the silk thread. If it is Tencel, the fibers are entangled with each other due to fibrillation on the surface, and the hand feels very smooth, waxy and soft. Modal often does not have this phenomenon.

Identification of low-elastic yarn, drafted yarn and pre-oriented yarn

No matter how you pull the low-elastic yarn (as long as the force is not too large), its The threads are always curled lengthwise. If the drafting wire is pulled with a little force, the longitudinal direction of the wire will become very straight. If the pre-oriented yarn is pulled with a little force, the yarn will be stretched a lot and the yarn will become straight in the longitudinal direction.

Identification of polyester composite yarn and draft yarn

If it is raw yarn, just check whether there are dots, and the composite yarn has two threads. When pulling, FDY is straightened first, and then broken, then POY is stretched, and finally broken; if it is double-twisted silk thread, they need to be untwisted, and then the silk thread is stretched hard. If it is composite silk, first FDY is straightened, then pulled, followed by POY, which is stretched, and finally broken; if it is a draft wire, pull with a little force, the wire is straightened, and then continue to use force, the wire is finally broken.

Identification of draft yarn, special yarn and hollow yarn

After alkali reduction of these three types of yarn, the characteristics of draft yarn and warping yarn The stems are still uniform, but the stems of the entire silk thread of special silk are different, and there is a bamboo effect, while the stems of the entire silk thread of hollow silk and special silk are different, and there is also a bamboo effect, but the bamboo effect is The fibers are particularly hairy. So we can use this to distinguish them.

The difference between PTT.FDY memory fiber and ordinary FDY fine denier imitation memory fiber

PTT.FDY memory fiber has two kinds of molecular chain segments. Molecular segments are flexible molecular segments and rigid molecular segments. If the flexible molecular segments exceed the rigid molecular segments, we call it MOMERRY memory fiber. If the rigid molecular segments exceed the flexible molecular segments, we call it PTT elastic fiber. , in short, the memory fiber thread has a certain elasticity when stretched, while the ordinary FDY fine-denier imitation memory fiber thread has no elasticity. Using this, we can easily identify the two fibers.

Identification of high elastic yarn and low elastic yarn

The difference in processing technology between low elastic yarn and high elastic yarn lies in the solution of high elastic yarn in deformation processing. The twist has not been shaped by the TCS heat pipe, so if the low elasticity yarn is used with relatively large force, the curl of the silk thread can be straightened, while the high elasticity yarn cannot be straightened with no amount of force, and it is made of high elasticity yarn. The finished fabric is elastic and can return to its original state after stretching.

Identification of first-twisted yarn and high-elastic yarn

The difference in processing technology between first-twisted yarn and high-elastic yarn is that the first-twisted yarn is pre-twisted A double twist is added, and then all are twisted by a false twister (the twisting direction of the first twist is the same as the double twist) to shape, and then untwisted (the twist is removed), and the wound yarn is thus The original bobbin is twisted first and has twist, while the high-elastic yarn has no twist; if it is a finished product, you only need to look at the elasticity of the surface elastic. If the elasticity is good, twist the silk first, and you can also look at the edge of the fabric. The edge of the fabric that is twisted first is like It is spiral-shaped, and the high-elastic yarn is as fluffy as the low-elastic yarn. If the finished yarn is untwisted and stretched, the curl degree of the first twisted yarn will be greater than that of the high stretch yarn. After the silk is twisted and untwisted, the silk thread will always be a little curled no matter how hard it is pulled. If you apply a little force, the silk thread will be broken; while high-elastic yarn will not be broken easily.

Identification of first-twisted silk and SSY silk

First-twisted silk is to twist the FDY silk thread on the double-twisting machine first, and then pass it through the false twister Twisting (twisting direction is the same as doubling the twisting direction), then untwisting (removing the twist), and winding the silk thread. SSY is a twin-screw spinning of high-shrinkage polyester chips and ordinary polyester chips. It is a parallel drawn yarn, so if it is the original package yarn, it is easy to distinguish, that is, the yarn twisted first has twist, but SSY does not; if it is a finished product, the SSY yarn will still have elasticity no matter how it is stretched. Curly, like a spring, and the silk is first twisted and then stretched after untwisting. It has no elasticity and the silk thread will break with a little force.

-End-

Source :Dr. Seshangfangbu

Disclaimer: The copyright of this article belongs to the original author. In order to respect intellectual property rights, China Yarn Network tries its best to mark the source of each article. If you do not want to reprint or infringe, please notify us to delete it.

What do you think of this topic? Welcome to forward, collect, comment and like. Don’t forget to follow me when you pass by. If you don’t follow someone, you are not allowed to leave~

Respecting intellectual property rights, China Yarn Network tries its best to mark the source of each article. If you do not want to reprint or infringe, please notify us to delete it.

What do you think of this topic? Welcome to forward, collect, comment and like. Don’t forget to follow me when you pass by. If you don’t follow someone, you are not allowed to leave~