Let’s learn about green and environmentally friendly bamboo fiber for textiles. How is it produced? What are its excellent performance and development prospects?

1. Source of raw materials and features

China has 39 genera and more than 500 species of bamboo plants, area, storage volume, bamboo product output and exports It ranks first in the world in terms of total amount, and its bamboo forest area accounts for 1/3 of the world’s total area. It is the country with the richest bamboo resources in the world and the country with the longest history of utilizing bamboo resources. It is known as the “Kingdom of Bamboo”.

Bamboo has a short growth period and can become useful in 2-3 years. It can be planted for a long time and can grow up to 3 feet overnight. It can Rapid growth and renewal can replace cotton, wood and other resources to achieve sustainable utilization.

Products made of bamboo fiber can be naturally degraded in the soil and will not cause any pollution to the environment after decomposition. They are natural, green and environmentally friendly Textile raw materials, it has broad application prospects in the textile industry.

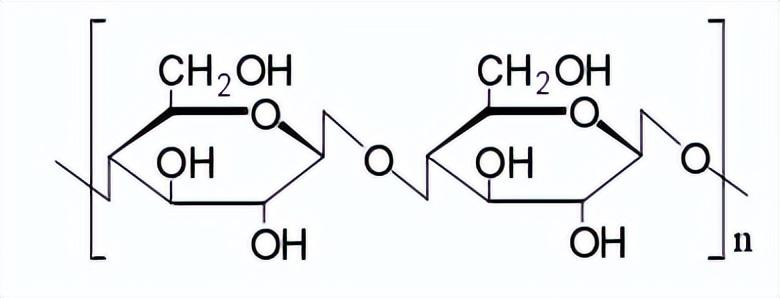

The chemical components of bamboo are mainly cellulose, hemicellulose and lignin. All three are high polysaccharides, and their total amount accounts for 90% of the dry mass of fiber. % or more, followed by protein, fat, pectin, tannin, pigment, ash, etc. What is very special is that bamboo contains a substance called bambooquinone, which has antibacterial and mite removal properties.

The main material making up bamboo fiber is cellulose. Its molecular formula is (C6H10O5)n, and its degree of polymerization is generally around 1,000,000. Its molecular structure can be represented by the following formula:

Bamboo fiber molecular structure

2. Bamboo fiber classification

The raw material of bamboo pulp fiber is bamboo. It is a type of bamboo fiber, but it is different from traditional bamboo fiber. Bamboo fiber is divided into two categories, namely bamboo original fiber and chemical bamboo fiber. Chemical bamboo fiber is further divided into bamboo pulp fiber and bamboo charcoal fiber.

Bamboo fiber

Bamboo raw fiberIt is a natural fiber that uses a combination of physical and chemical methods to directly extract fibers from bamboo, and then spins and weaves garments. The preparation process is: bamboo material → making bamboo chips → steaming bamboo chips → crushing and decomposition → biological enzyme degumming → carding fibers → textile fibers. Although bamboo raw fiber has superior performance and the preparation process is simpler than bamboo pulp fiber, the process requirements are high, the production is difficult, and it is difficult to mass-produce.

Bamboo pulp fiber is made by crushing bamboo to extract cellulose and making pulp, which is then chemically dissolved into viscose bamboo Pulp, and then fibers made by wet spinning, belong to the category of chemical fibers. Prepared with common viscose and modal fibersThe speed ranks first among all fibers [4].

Therefore, bamboo pulp fiber textiles make people feel particularly cool and comfortable. When used in winter and spring, they are both fluffy and comfortable and can eliminate excess heat and moisture. They are called ” “Breathing” ecological products.

(2) Good antibacterial performance

Because bamboo contains bamboo quinone, which has antibacterial and mite-removing properties, bamboo fiber has natural antibacterial properties and will not cause allergic reactions to the skin.

(3) Has deodorizing effect

Bamboo pulp fiber has natural deodorizing properties, mainly because the fiber contains deodorizing substances such as chlorophyll and sodium chlorophyll, which can remove odors through odor adsorption and oxidative decomposition.

In addition, bamboo pulp fiber perspires quickly, making the living environment of microorganisms poor, and it can also achieve the deodorizing effect.

(4) UV protection

Bamboo pulp fiber contains chlorophyll copper, which is a safe and excellent ultraviolet absorber and can effectively block ultraviolet radiation to the human body.

(5) Excellent dyeing performance and dye uptake

Bamboo pulp fiber has a porous network structure and low crystallinity. Reactive dyes can be quickly adsorbed on the bamboo pulp fiber, with high initial dyeing rate and short dyeing time.

Hydrogen bonds and van der Waals forces form multi-layer physical adsorption between reactive dyes and bamboo pulp fibers, resulting in high dye uptake.

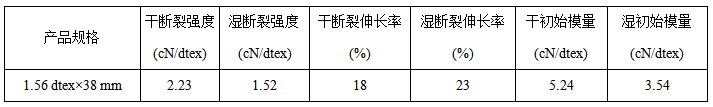

(6) Mechanical properties

Table Bamboo Test results of mechanical properties of pulp fibers[5]

5. Application fields

Due to the excellent performance characteristics of bamboo pulp fiber, it is widely used in It is widely used in the textile field.

(1) Knitted fabric

Bamboo Pulp Knitted fabrics produced from fiber have the advantages of breathability, moisture absorption, antibacterial, and deodorization, so they are particularly suitable for personal wear as underwear and socks.

Bamboo fiber underwear and socks

( 2) Textile towels

Bamboo pulp fiber towel products have the characteristics of moisture absorption, quick drying, softness and comfort. Related products on the market mainly include Bath towels, hand towels, square towels, etc. are often woven with cotton yarn as the ground yarn and weft yarn, and bamboo pulp fiber yarn as the loop.

Bamboo pulp fiber towel

(3) Bedding

Bamboo pulp fiber bedding products mainly include bedding sets and quilt products. Bamboo pulp fiber can be blended with other textile materials. Bamboo pulp fiber blended with linen can optimize the dryness and breathability of bedding; blended with wool to make the product softer and warmer; blended with silk to increase the noble temperament of the fabric.

Bamboo pulp fiber sheets

(4) Hygiene products

Bamboo pulp fiber products are porous, breathable and antibacterial, and have a good antibacterial effect on harmful bacteria, so they can be used in hygiene It is widely used in materials such as sanitary napkins, masks, panty liners, etc.

Bamboo fiber changing pad

Pulp fiber underwear and socks

(2) Towel textiles

Bamboo pulp fiber towel products have the characteristics of moisture absorption, quick drying, softness and comfort. Related products on the market mainly include bath towels, towels, square towels, etc. Cotton yarn is often used as the ground yarn and weft yarn, and bamboo pulp fiber yarn Woven as terry.

Bamboo pulp fiber towel

(3) Bedding

Bamboo pulp fiber bedding products mainly include bedding sets and quilt products. Bamboo pulp fiber can be blended with other textile materials. Bamboo pulp fiber blended with linen can optimize the dryness and breathability of bedding; blended with wool to make the product softer and warmer; blended with silk to increase the noble temperament of the fabric.

Bamboo pulp fiber sheets

(4) Hygiene products

Bamboo pulp fiber products are porous, breathable and antibacterial, and have a good antibacterial effect on harmful bacteria, so they can be used in hygiene It is widely used in materials such as sanitary napkins, masks, panty liners, etc.

Bamboo fiber changing pad