Denim originated earlier and has a long history of development.

According to some research, in Europe between the 16th and 17th centuries, twill weave fabric, called Denim, or denim, had appeared , translated into English as tanning. Most modern denim is this kind of twill fabric.

In the late 1840s, a man named Jean in the American West chose to make a canvas A pair of work clothes with novel style and strong texture is very popular among people.

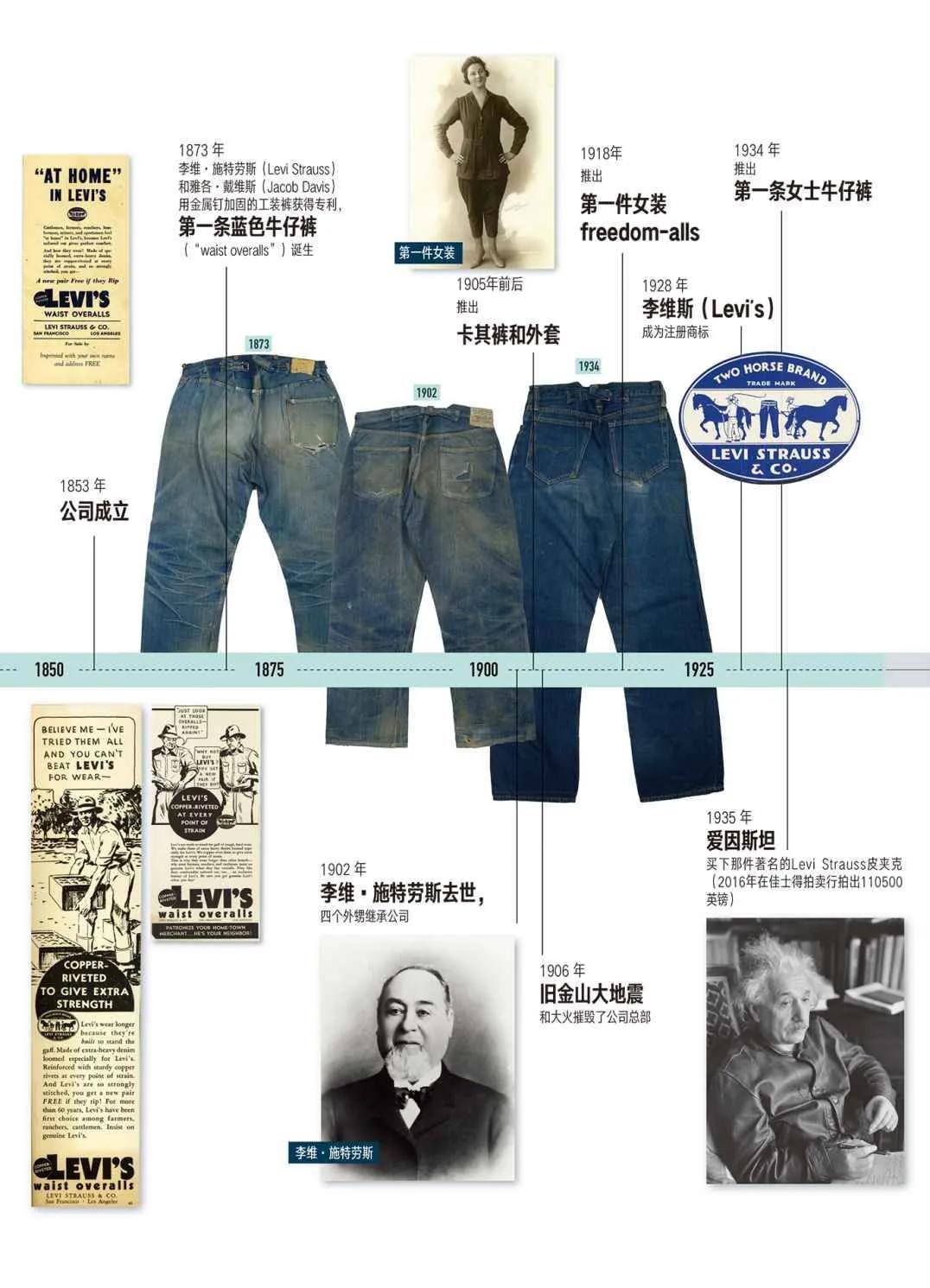

Levi Strauss, a blues businessman who immigrated to the United States in 1873

Strauss is known as the father of cowboys. He used indigo-dyed cotton yarn as warp yarn and natural cotton yarn as weft yarn to make twill cloth, and then used this cloth to make work pants. Later, copper nails were used to reinforce the pockets, and gradually evolved into the prototype of jeans with low waist, straight legs and tight hips. In 1893, he applied for a patent under the name “Rivet Suit”. This was quickly accepted by miners and herdsmen in the western United States and was called “Blue Joan”. Levi Strauss Company was officially established in 1897, focusing on the production of denim and denim garments. The company has now developed into one of the largest garment manufacturing companies in the world.

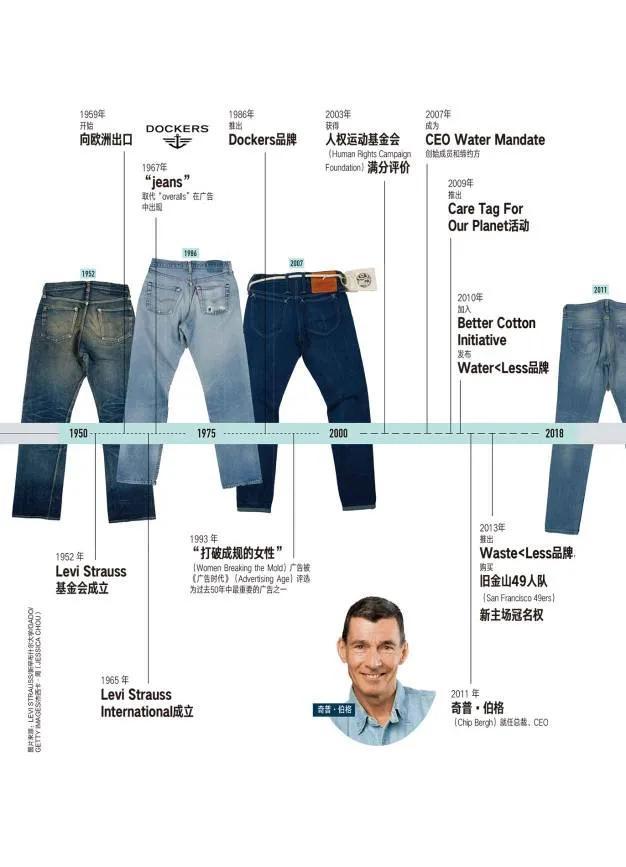

Since 1960, Levi’s has launched a series of washed jeans. By 2007, Levi’s found that every pair produced Levi’s jeans consume an average of 42 liters of water, resulting in a waste of too much water, so Levi’s company began to explore new production processes and launched “Levi’s

“WaterLess” series of jeans, the manufacturing cost of this kind of jeans is almost the same as that of ordinary jeans, but the water consumption is reduced by 28%. In response to the waste of water resources during cotton planting and processing, Levi’s has also joined the “Better Cotton Program”

Cotton Initiative), assisting cotton growers and partners around the world to improve planting techniques and reduce water consumption.

In addition, Levi’s reduces the use of many chemicals in production; provides consumers with care instructions to encourage Consumers “wash less, wash cold, dry, and donate when not needed.”

In terms of recycling, Levi’s cooperates with many organizations to recycle old clothes in landfills and use new technologies to make them Reuse.

In the late 1970s, China opened the door to reform and opening up. First, the denim trend spread from Hong Kong to Guangdong. In the early 1980s, Guangdong, Shanghai, Jiangsu, and Liaoning successively produced denim and denim garments. Guangdong took the lead in introducing a production line for the production of indigo denim and introduced a complete set of denim garment production equipment. By the mid-1980s, denim washing technology developed rapidly, and there were many washing processes such as stone grinding washing and snowflake washing. Over the past 20 years, my country’s denim and denim garments have experienced rapid growth, decline and structural adjustment. my country has now become the world’s largest denim and denim garment production base. Industrial development is currently underway and continues to develop towards the high end.