1Glue and leather ironing

Glue and leather hot stamping is to laser-burn the rubberized leather blank. After the pattern is burned out, it is placed on the cut piece or garment to be printed for appropriate heating and pressure to make the pattern hot. Adhere to cut pieces or garments.

Generally used Make some relatively simple single-color patterns, and it will be easier for the glue and leather to fall off the clothes.

2Convex and concave embossing

First make a mold with a pattern, and then heat press it on a piece padded with velvet or special glue to punch it out The shape of the pattern. Convex and concave embossing printing is printed directly on clothes. Because each pattern is first made as a pattern mold, this process is relatively expensive to start with. Generally used to make some simple patterns with thick lines.

3 spray colors (digital printing)

Spray For coloring, a special spray gun is used to spray water-based slurry on finished clothes or cut pieces. It can also be used as a paintbrush, or it can be used to make a pattern and spray patterns into the pattern.

4Pressed, laminated

Pressed velvet printing is to first make a pattern mold, and then heat press it on velvet or special glue. on to make it punch out the shape of the pattern.

This process is also used for imitation peach skin clothes.

5 discharge printing

The principle of discharge printing is to The color of the fabric tissue fibers is pulled out, turning it into another lighter color, which is similar to the washing effect. The discharge printing process is complicated, prone to defects, and costly. However, discharge dyeing has a better effect than resist dyeing because the pattern is more delicate, the outline is clear and the edges are not exposed. Because this printing method mostly uses carved white powder, it is also called carved printing. Discharge printing also has certain requirements for fabrics. There are many fabrics that can be used for discharge printing, but it is generally better to use hollow pure cotton fabrics.

6 Burnout printing

Burnout printing, in many A printing process in which corrosive chemicals (such as sulfuric acid, ALCL3, etc.) are printed on fabrics composed of component fibers. After drying, baking and other post-processing, a certain fiber component is destroyed to form a pattern.

Mostly used on velvet fabrics.

7 Pearl printing

Bead printing is relatively demanding It is a kind of technology that only a few factories can do well now, and almost no ordinary factories have this technology.

8 ink printing

It has one advantage, glue When printing on smooth fabrics, such as windbreaker fabrics, the color fastness is generally very poor and can be scraped off with strong fingernail scraping, but ink can overcome this shortcoming.

When making windbreakers, ink is generally used.��

9 velvet foam printing

Velvet foam Printing and foam printing are three-dimensional printing, but there are certain differences in structure: the internal structure of the printing material is different, and visually the velvet foam printing product has a velvet embroidery effect and a relief effect, but foam printing only has a relief effect. Velvet foaming is physical foaming, and foam printing is chemical foaming.

10 crack printing

is derived from glue Basically, a certain shrinkage reaction material is added to the slurry and completed through a certain process. As the name suggests, the effect produced by crack printing is like the effect of dry ground or cracking effect

11 color changing functional printing

Textile printing with color-changing function can also be called textile shadow printing, which means that the color of the pattern on the textile changes with the changes in ambient temperature, light and shade, and the dryness of the fabric. Changes in humidity, etc., cause the color of the pattern to flicker and appear. That is to say, the color of the pattern on the fabric changes from conventional “static” to novel and unique “dynamic”, and the change in color is generally a reversible change. Color-changing textile printing technology is to print modern high-tech materials on textiles. This kind of color-changing textiles can be made into summer clothes, towels, actor clothes, work clothes, beach pants, swimwear, children’s clothing, etc.

T shackles, umbrellas, ponchos, curtains, etc. When people wear or use it, they feel the unpredictable fun and achieve unique dynamic effects.

12 foam printing

As the name suggests, it is foamed Glue is also changed from glue. First, the prepared slurry is printed on the clothing, and then processed by a high-temperature machine. The pattern will soak up. The three-dimensional effect is very good, but it is a bit soft, but the clothes have been worn and washed many times. After that, the three-dimensional effect will slowly disappear and be flattened.

13 glue

is a kind of glue that can be compared with thick plates The more three-dimensional variety is generally used to make rubber stamps, mostly on men’s clothing. When used on women’s clothing, it is used to create flower shapes. The disadvantage of glue is that it can be easily broken off if you exert too much force.

14 luminous printing

is a kind of special printing. It uses light-storing materials and additives such as adhesives to print patterns. After being illuminated by sunlight or other light sources, the luminous powder stores energy and jumps from a low-energy state to an activated state. After dark, it can emit yellow-green light. , with special visual effects. Luminous printed fabrics are generally used in evening wear, casual wear, children’s wear, and interior decoration.

15 thick board paste

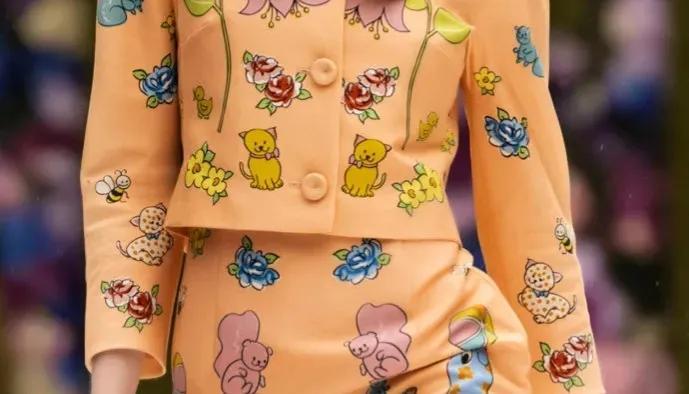

is the source Based on glue, it is like multiple layers of glue being printed repeatedly. It can achieve a very neat three-dimensional effect. Generally speaking, the process requirements are relatively high, so small printing factories generally cannot print well. We don’t even have this technology, let alone printing it, but it is a printing method that is currently popular all over the world! It is generally suitable for use on more sports and leisure models. The patterns generally use numbers, letters, geometric patterns, lines, etc. , the lines should not be too thin. Some people also use it to print floral patterns in a unique way, which can be seen on leather or thicker fabrics for autumn and winter clothing.

16 stone mortar

If the mortar is neat , then the stone slurry is random. It looks like blocks or strips of stone or mud shapes. It is a relatively new type of printing and is often seen in casual men’s clothing.

Used to print floral patterns, found on autumn and winter clothing leather or thicker fabrics.

16 stone mortar

If the mortar is neat , then the stone slurry is random. It looks like blocks or strips of stone or mud shapes. It is a relatively new type of printing and is often seen in casual men’s clothing.