Fiber is the prerequisite for the development of textile products, rich and colorful Textile products require ever-changing textile raw materials. The emergence of special-shaped cross-section fibers has greatly enriched fiber varieties and provided abundant raw materials for the development of new clothing fabrics and new textile products. Therefore, special-shaped cross-section fibers have been widely valued, developed and utilized in the textile market.

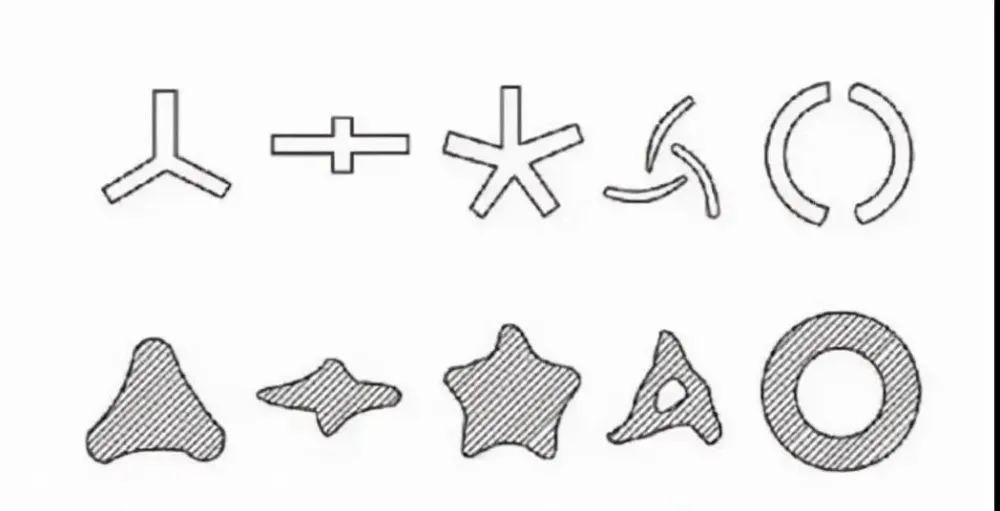

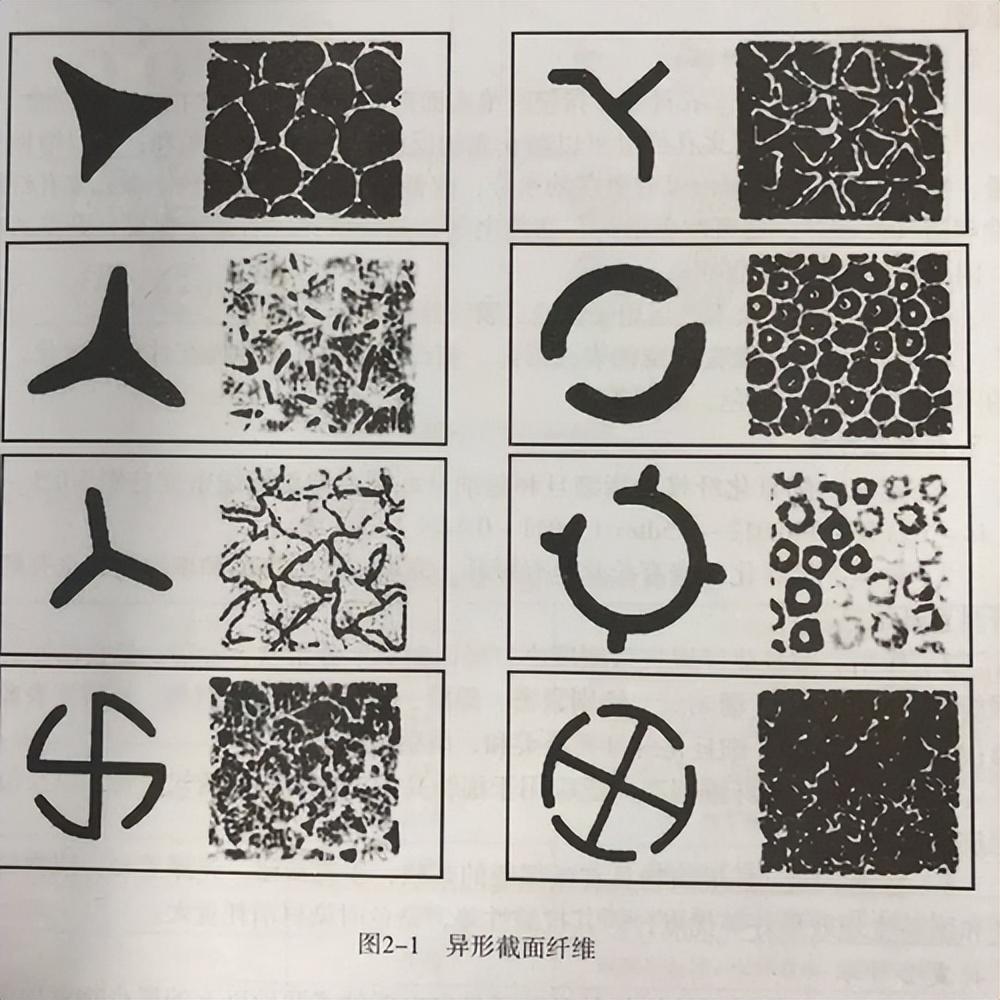

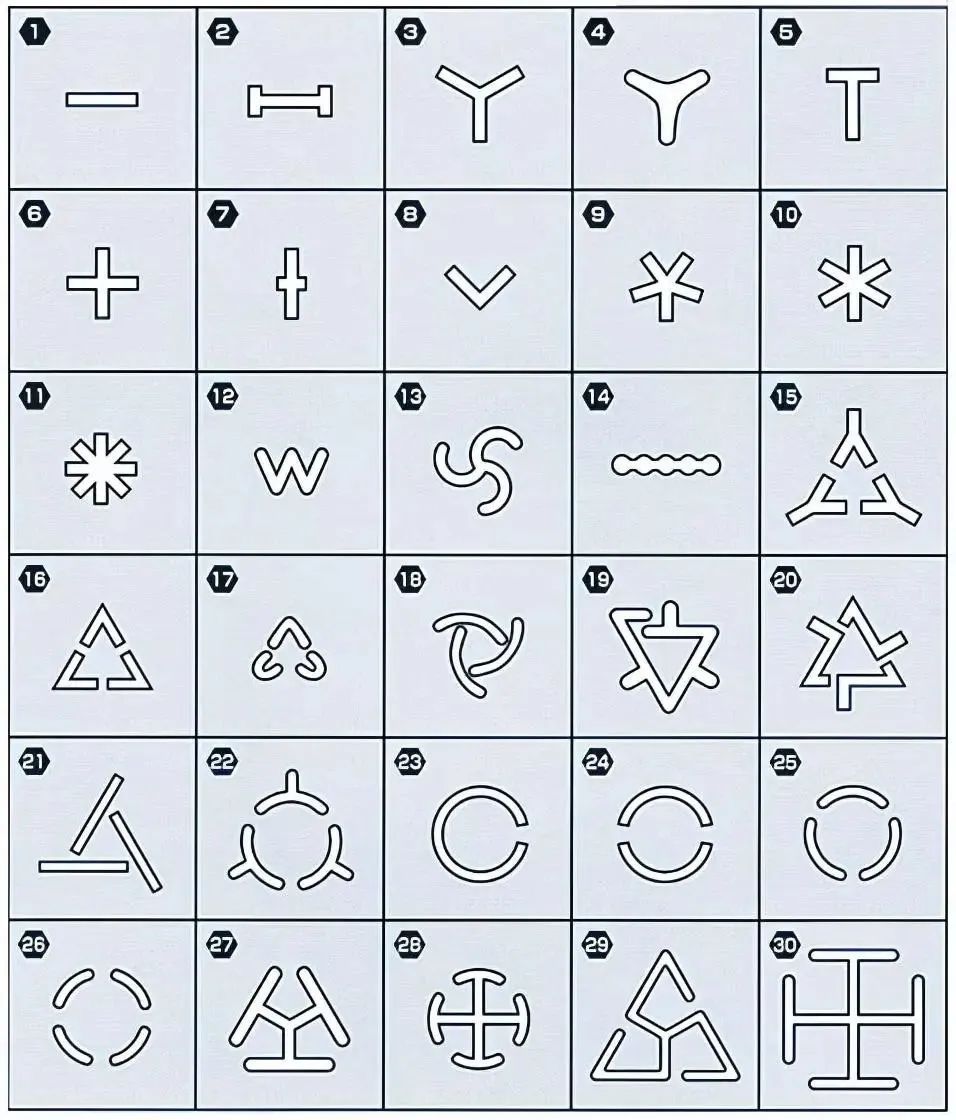

my country’s special-shaped sections The development of fibers began in the mid-1970s, with the research focus on spinneret manufacturing technology. In recent years, with the development of textile technology, spinneret manufacturing technology has made great progress, spinning technology has become mature, and a complete production technology chain has been formed. Special-shaped cross-section fibers have also developed from the original triangular and hollow cross-sections to today’s various special-shaped varieties, such as: pentagonal, trilobal, Y-shaped, dumbbell-shaped, oval, L-shaped, lotus-shaped and special-shaped hollow, etc., each All have their own characteristics.

What is special-shaped cross-section fiber

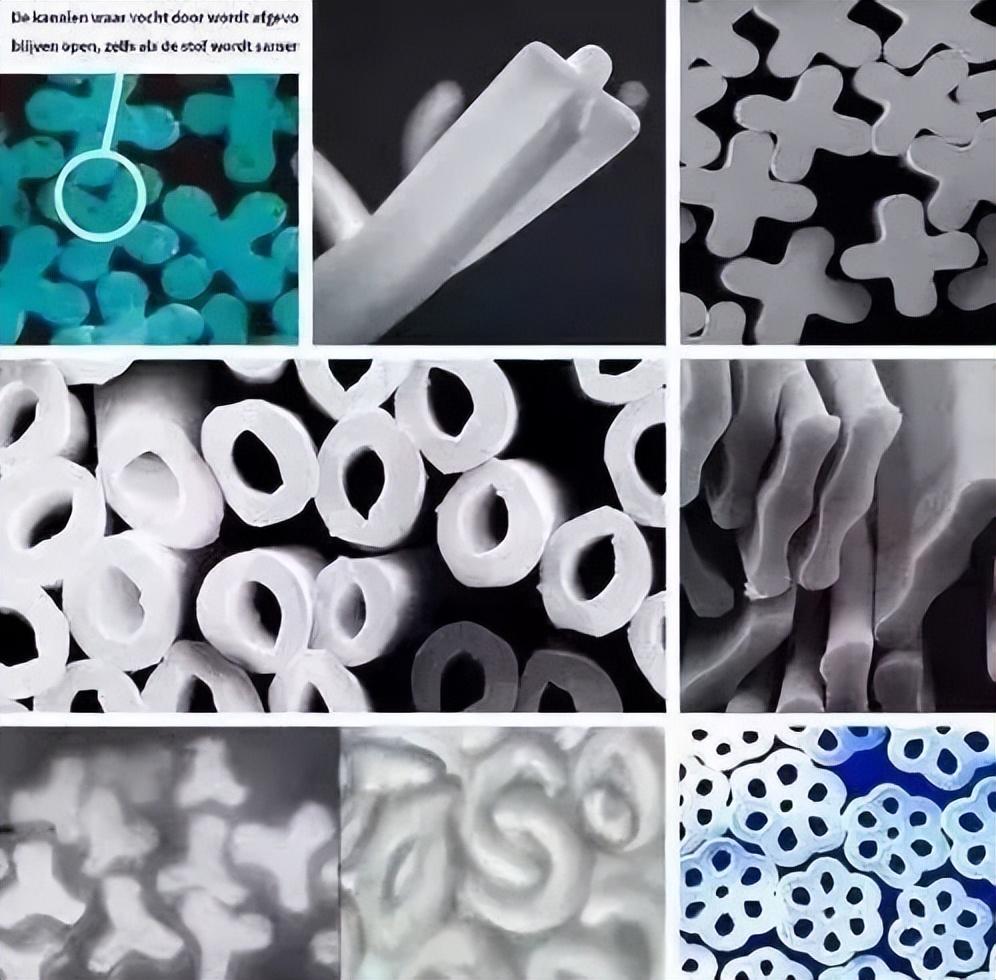

The so-called special-shaped fiber is to make the same synthetic fiber into a fiber with a deformed cross-section , there are two main types of forms: one is the non-circular shape of the cross-section, and the other is the hollow and composite cross-section. Compared with round fibers, special-shaped fibers have many characteristics.

Development of special-shaped cross-section fibers

Special-shaped cross-section fibers were first introduced by DuPont in the United States in the early 1950s. Triangular cross-section, and then Germany developed a pentagonal cross-section. In the early 1960s, the United States developed hollow fibers with excellent thermal insulation properties. Subsequently, countries such as the United Kingdom, Italy, and the former Soviet Union also developed such products.

Due to The manufacturing and textile processing technology of special-shaped fibers is relatively simple, with low investment and quick results, so it develops relatively quickly. The development of special-shaped fibers in my country was in the mid-1970s. The processing technology was improved in spinneret manufacturing and the spinnability of the boards was improved.

Spinning method of special-shaped cross-section fibers

1. Direct method: spinneret holes with similar fiber cross-section shapes Direct spinning to obtain fibers with special-shaped cross-sections is also the most commonly used method.

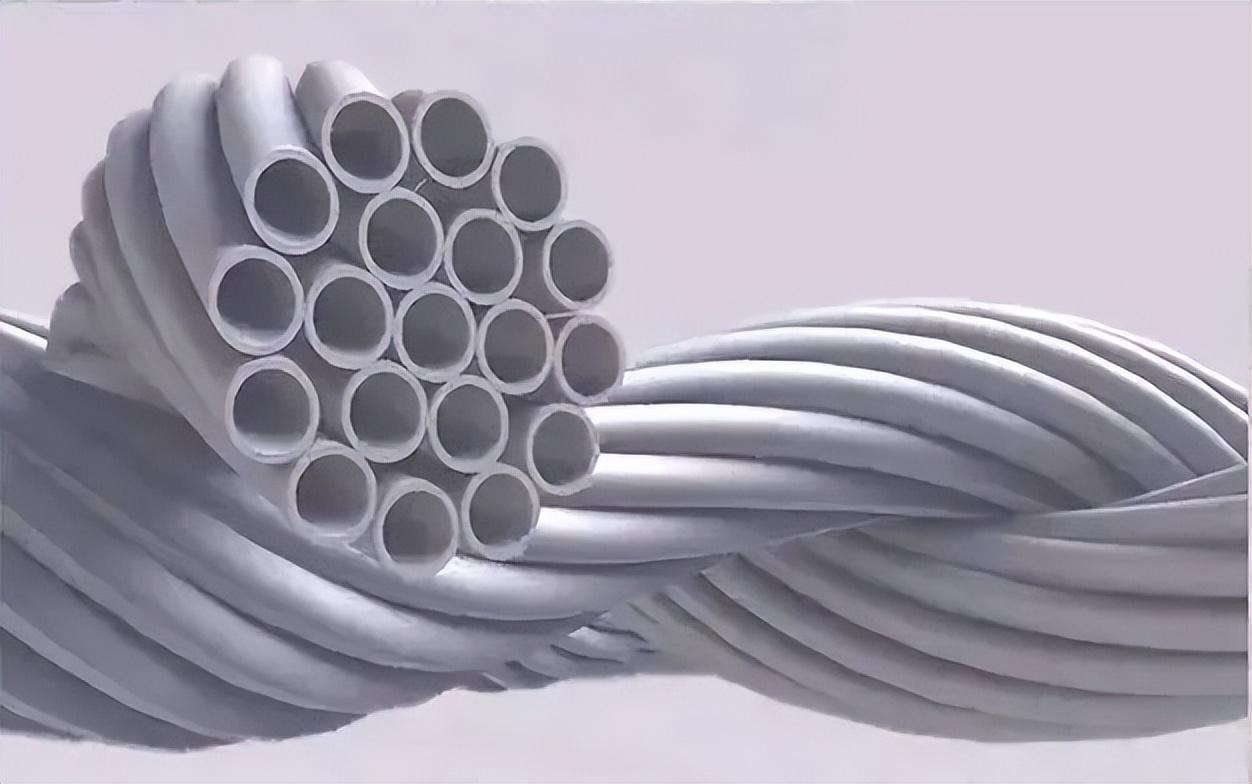

2. Expansion Adhesion method: The spinneret holes are made into circular holes, arc holes, slits, etc. that are close to each other. When spinning, due to the exit expansion effect of the spinning fine stream, they stick to each other to form special-shaped fibers. Hollow fibers are often used. This method is used for spinning.

3. Compound Spinning method: Two or more high molecular polymers pass through a special spinneret assembly, and each component is ejected through the spinneret hole in a certain proportion.

4. Roll Preparation method: Use two overlapping spinnerets, each with a different spinneret hole shape, to produce special-shaped yarn.

Special-shaped cross-sectionCharacteristics of fibers

1.

Glossy: The biggest feature of special-shaped fiber is its unique optical effect. The reflection intensity of light on the surface of circular cross-section fibers has no relationship with the direction of incident light, but the reflection intensity on the surface of special-shaped fibers changes with the direction of incident light. This optical characteristic of special-shaped fibers enhances the luster of the fiber, allowing the human eye to receive different optical information in different directions and positions, resulting in a good sensory experience.

2. Resistance Wrinkling and spinning properties: The elastic modulus of special-shaped fibers is higher than that of circular cross-sections, so they have stronger resistance to deformation and good wrinkle resistance. Just like an I-beam of the same length and weight has better bending resistance than a round steel.

3. Fluffy Performance and breathability: Generally speaking, the coverage and fluffiness of special-shaped fibers are better than those of ordinary synthetic fibers, and the fabric feels thicker, fluffier, fuller and lighter. The more complex the cross-section of the special-shaped fiber, or the higher the degree of fiber special-shape, the better the fluffiness and air permeability of the fiber and fabric.

4. Resistance Pilling and abrasiveness: After fiber deformation, due to the increase in fiber surface area, the cohesion between fibers in the thread increases, and the pilling phenomenon is greatly reduced.

5. Dyeing Anti-fouling and anti-fouling properties: Due to the large surface area of special-shaped fibers, the coloring speed is accelerated and the dyeing rate is significantly increased.

Applications of common special-shaped cross-section fibers

1. Triangular cross-section fiber: This type of fiber has a flash effect and is generally used in fabrics It plays an embellishment role and can be blended or interwoven with other fibers to make glittering wool, scarves, spring and autumn sweaters, women’s outerwear, evening gowns, etc. All of these products have glittering effects.

2. Three Leaf-shaped cross-section fiber: In addition to excellent optical properties, this type of fiber also has a large friction coefficient. Therefore, the fabric feels rough, thick and durable, and is more suitable for outerwear fabrics. The fleece fabric made of trilobal fibers can keep the pile plump and upright, and has good mechanical bulk.

3. Hollow Cross-section fiber: superior performance, excellent warmth retention and fluffiness. It can be used to make medium-thick tweed with light texture and full hand feel, and can also be used to make various warp knitted fabrics with low transparency, good warmth retention, comfortable hand feel and soft luster.

4. Pentagon Cross-section fibers: This type of fiber is representative of star-shaped and polygonal fibers. Polygonal low-elastic yarn can be made into wool-like, linen-like, knitted or outerwear fabrics. The product has a soft luster, light feel and anti-pilling.

5. Y Type-shaped cross-section fiber: The fiber porosity reaches 40%, which is more than double the porosity of circular cross-section. These pores provide capillary channels for sweat and moisture to flow, which is beneficial to moisture absorption and perspiration. Precisely because of its light weight, water-absorbent and sweat-absorbing properties, easy washing and quick-drying, it is commonly used in the preparation of sportswear, training wear and other fabrics.

6. Double Cross-section fiber: moisture-absorbing, quick-drying, and crisp feel. Socks knitted from this type of fiber have good wearing properties and can solve the problem of socks prone to prolapse and falling. Moreover, at the same fineness, this type of fiber has a large cross-section and low material cost.

7. Flat Shaped cross-section fiber: It has a warm-keeping effect, strong gloss, and soft hand feel. It can be used as a long-hair fiber in imitation fur and has been widely used in warp knitting double needle beds.

Special shape The unique advantages of cross-section fibers are incomparable to ordinary round fibers. In recent years, they have developed faster and faster, and their varieties have become more abundant. Therefore, the development of fabrics using fibers with different cross-sections is of great significance to improving the international competitiveness of my country’s textile industry. At the same time, it also has broad market development space.