What is conductive fiber

Conductive fiber usually refers to under standard conditions (temperature is 20℃, relative humidity is 65% ) resistivity is less than 107 Ω. cm fiber is a general term for fibers made entirely or partially of conductive materials or sub-conductive materials such as metals, conductive organic substances, and antistatic agents.

The development history of conductive fibers

- Early conductive fibers were metal fibers. However, due to the poor bending resistance and flexibility of metal conductivity, they did not have the relatively high mechanical performance requirements of smart textiles, so they were rarely used directly. in flexible wearable smart textiles.

- The discovery of conductive polymers ushered in a new era of conductive fibers. For example, the redox doping of Lewis acid AsF5 increases the conductivity of polyacetylene (PA) by 13 orders of magnitude, reaching 103S/cm, which is comparable to the conductivity of copper, gold, etc.

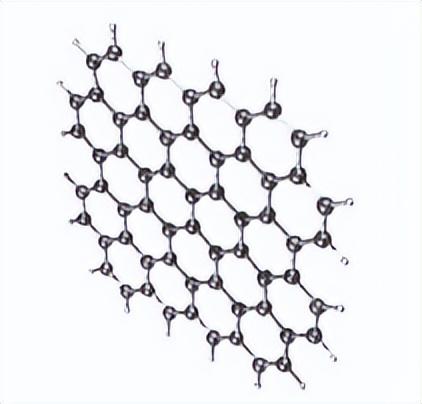

- With the development of science and technology, the excellent mechanical and electrical properties of carbon-based materials have been revealed in related research. Taking graphene as an example, the π electrons in it can move freely, so graphene has super conductivity.

Preparation of conductive fibers

Common preparation methods of conductive fibers mainly include: Bit preparation method, surface treatment method, carbon treatment method.

- In-situ preparation method

- In-situ preparation method includes direct spinning method, doping spinning method and Composite spinning method. Among them, the fibers prepared by the composite spinning method not only have good mechanical and electrical properties, but are also easy to cohere with other fibers and be blended or interwoven.

- Surface treatment method

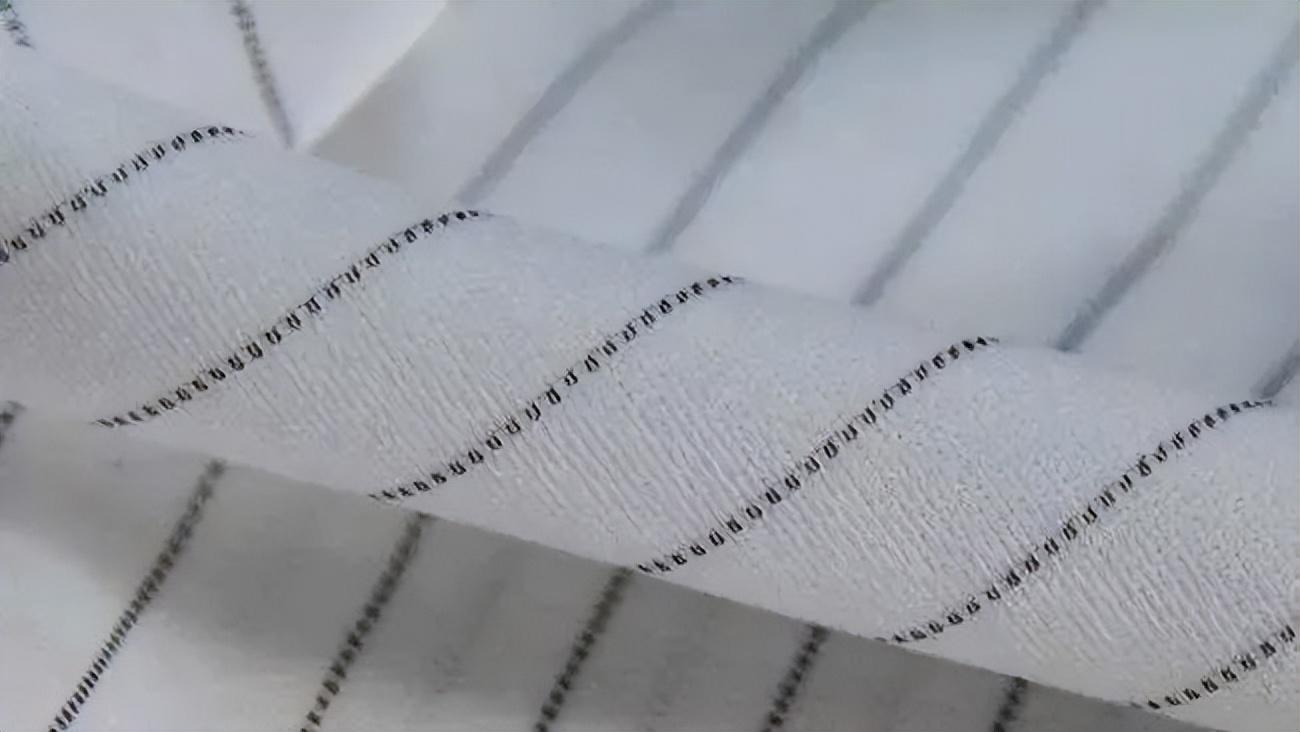

- Surface treatment method refers to the surface treatment of synthetic fibers, mainly including physical impregnation Conductive fibers are prepared by coating, plating, copolymerizing, grafting, etc. to cover the surface of the substrate with conductive substances or forming a conductive film.

- Carbon treatment method

- Use the current carbonization treatment technology to deeply process the fiber. Since the fiber has more carbon atoms in the main chain, the conductivity of the fiber is improved. But at the same time, it has high modulus, lacks toughness, and has limited scope of application.

Application research of conductive fibers

- Metal material fiber.

- Metal itself is hard and does not have the resilience and extensibility required for wearable textiles. In current research, metal materials are generally composited with other materials. For example, the elastic recovery of polyurethane fibers and the conductivity of copper alloys are used to provide excellent stretchability and high conductivity.

- Conductive polymer fibers.

- Generally, conductive polymers and other materials are prepared by wet method and melt spinning to obtain composite conductive fibers. For example, composite fibers prepared from conductive polymer PSS and single-walled carbon nanotubes have excellent mechanical and electrical properties. With the development of conductive polymers, conductive polymers can be used alone or combined with fiber optic sensors for monitoring temperature, pressure, and electromagnetic radiation.

- Nanocarbon materials

- Nanocarbon materials are divided into zero-dimensional carbon nanospheres, fullerenes, one-dimensional carbon nanotubes, carbon nanofibers, and two-dimensional graphene. Commonly chosen fibers are carbon nanotubes and graphene. For example, flexible conductive composite fibers prepared with SBS as the base material and multi-layer graphene as the conductive component have high capacitive properties, low power loss and good elasticity. After thousands of stretching cycles There is still more than 90% capacitance retention rate.

Conclusion

Conductive fibers can be used in various sensors, capacitors, drivers and other electronic components development and integration. Not only must it meet the most basic stable conductivity

It also needs to have stretch recovery and comfort as a flexible wearable textile material. Although various wearable flexible smart electronic products are still in the early stages of research and development, integrating conductive fibers with people’s daily clothing willIt will be a major development direction of wearable electronic devices.