Wool-like fiber

Wool-like fiber is to use chemical fibers to imitate the style characteristics of wool fabrics to produce chemical fiber fabrics, thereby achieving the purpose of replacing wool with chemical fibers.

Faux wool

Performance requirements of wool-like chemical fibers:

1. Fleece-like chemical fiber The tensile properties should be similar to those of wool. Some chemical fibers have excessive breaking power and good toughness, but their anti-pilling performance deteriorates. Therefore, the breaking work of wool-like chemical fibers is not as high as possible, but should be controlled within an appropriate range. It is generally believed that the strength and breaking power of wool-like chemical fibers only need to reach the level of wool.

2. Fleece-like chemical fibers should have appropriate curl. By curling the wool-like fibers, wool-like curls can be formed, giving the fabric a fluffy, soft, elastic feel and style with a strong wool-like feel.

3. The compression initial modulus of the wool-like chemical fiber aggregate should be appropriately low, the compression density should be moderate or higher, and the compression elastic recovery rate should be high, because compression elasticity is closely related to the feel, softness, elasticity, and fluffiness of the fabric. Sex and other styles are related.

Technical approach to chemical fiber imitation wool

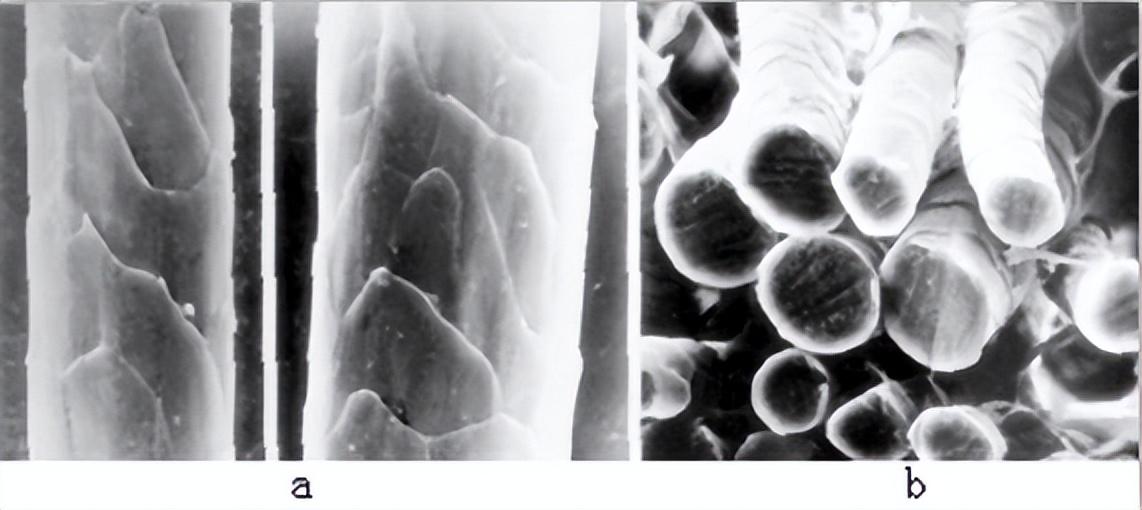

Wool structure diagram

There are two main technical approaches to chemical fiber imitation wool: One is to imitate the morphological structure and performance of wool fibers and develop wool-like fibers; the other is to imitate the appearance, style and performance of fabrics Wool fabrics, through the synergy of spinning, spinning, weaving, dyeing and finishing, produce fabrics with wool fabric style characteristics and performance.

1. Short fiber imitation wool

Short fiber imitation wool is first simulated from the length and fineness of the fiber to make it close to the average length and average linear density of wool, forming special specifications such as 2.75dtex × 51mm; 3.33 dtex × 76mm.

The raw materials of short fiber imitation wool are mainly polyester, nylon, nylon, viscose, etc.

2. Medium-long fiber imitation wool

Mid-length fiber is a kind of chemical fiber with medium cut length. Its length is generally 51-76mm, between cotton type (38-41mm) and wool type (78-124mm).

There are two methods for producing high shrinkage acrylic fiber There are two methods, namely stretching method and chemical modification method. The stretching method is to stretch the fiber macromolecular chain multiple times when it is higher than the glass transition temperature of acrylic fiber, and orient it along the fiber axis, and then cool it rapidly , which temporarily fixes the shape and tension of the fiber macromolecular chain. When acrylic fiber is treated in a relaxed state, it causes significant shrinkage of the fiber in the length direction. The chemical modification method is to increase the content of the second monomer methyl acrylate. Or use a thermoplastic second monomer to copolymerize with acrylonitrile to reduce the tightness of the arrangement of fiber molecules, which can significantly increase the shrinkage of acrylic fiber.

(2) High shrinkage polyester

Production method

High shrinkage polyester is generally obtained by modifying crystalline polyester. There are two main production methods: one is to use special spinning and drawing processes, such as POY yarn After low-temperature stretching, low-temperature setting and other processes, high-shrinkage polyester with boiling water shrinkage of 15%-50% can be produced; the other is to use chemical modification methods to produce modified copolyester and then spin.

2. Special-shaped fiber

Special-shaped fibers refer to fibers with a non-circular cross-sectional shape.

Production of special-shaped fibers

Special-shaped fiber is It is spun with special-shaped spinnerets with non-circular cross-sections. It is generally produced by melt spinning method or solution spinning method. It mainly includes triangular, polygonal and multi-lobed shapes, flat shapes, hollow shapes and multi-shaped ones. Hollow shape. The purpose is to improve the feel, gloss, hygroscopicity, fluffiness and other properties of synthetic fibers.

3. Composite fiber

Composite fiber is composed of two or more polymers, or the same polymer with different properties, compounded in a certain way. Composite fibers can be made into fibers with special functions such as wool-like high curl, easy dyeing, flame retardant, antistatic, and high moisture absorption. Composite fibers can be mainly divided into side-by-side type, sheath-core type and matrix-fibril type according to the distribution and arrangement of each component in the fiber. Side-by-side composite fibers can be made into crimped fibers by selecting components with different shrinkage rates, so they are widely used in chemical fiber imitation wool.

Synthetic fiber wool-like product development

Wool The natural curly nature of wool is due to the presence of a bilateral structure of cortical and partial cortical cells in wool. In order to imitate the crimp characteristics of wool fibers, two components with different shrinkage rates are used when spinning chemical fibers. Side-by-side composite fibers with different shrinkage components on the same fiber cross section can be produced, such as polyamide and Polyester, polyurethane polyether and polyacrylonitrile are self-curling side-by-side two-component composite fibers. The fibers have good curling durability, fluffiness, resilience and warmth, and the fabric has a smooth and waxy feel. The appearance is natural, gorgeous and elegant, and the imitation wool effect is good.

4. Flame-retardant fiber

In order to imitate the non-flammable properties of wool fibers, wool-like chemical fibers can be made into flame-retardant fibers.

Production of flame-retardant fibers

Flame retardant Fibers are generally produced by copolymerization or blending methods. The copolymerization method uses monomers containing flame-retardant elements (such as Cl. Br, P, etc.) to prepare flame-retardant fiber-forming polymers through copolymerization, and then spins them to obtain flame-retardant fibers. The blending method is to add flame retardant to the spinning melt or solution, mix and spin to produce flame retardant fibers.

Currently, commonly used wool-like flame-retardant fibers include: flame-retardant polyester, flame-retardant nylon, flame-retardant acrylic, etc.

5. Microfiber

Japan calls fibers with a linear density lower than 0.3 dtex microfibers. Microfiber has the advantages of being soft to the touch and comfortable to wear.

Production of microfiber

Super fine There are two main types of fibers: direct spinning and composite spinning. The direct spinning method uses traditional melt spinning method to produce ultrafine fibers. The composite spinning method uses composite spinning technology to spin composite fibers, and then separates the various components in the composite fibers from each other through mechanical or chemical treatment, or uses a solvent to separate one component of the sea-island composite fiber. Dissolve to obtain microfiber.

e-color: #A3A3A3;”>Production of flame-retardant fibers

Flame retardant fibers are generally produced by copolymerization or blending methods. Copolymerization The method is to use monomers containing flame-retardant elements (such as Cl. Br, P, etc.) to prepare flame-retardant fiber-forming polymers through copolymerization, and then spin them to obtain flame-retardant fibers. The blending method is Flame retardant is added to the spinning melt or solution, mixed and then spun to produce flame retardant fibers.

Currently, commonly used imitation fur Flame-retardant fibers include: flame-retardant polyester, flame-retardant polyester, flame-retardant acrylic, etc.

5. Microfiber

Japan calls fibers with a linear density lower than 0.3 dtex microfibers. Microfibers have the characteristics of soft hand feeling and comfortable wearing. Advantages.

Production of microfiber

There are two main types of ultrafine fibers: direct spinning and composite spinning. The direct spinning method uses traditional melt spinning method to produce ultrafine fibers. The composite spinning method uses composite spinning technology to spin composite fibers, and then separates the various components in the composite fibers from each other through mechanical or chemical treatment, or uses a solvent to separate one component of the sea-island composite fiber. Dissolve to obtain microfiber.