Water-soluble embroidery

Water-soluble embroidery (water-soluble lace) is a major category of embroidery lace. It uses water-soluble non-woven fabric as the base fabric, uses viscose filament as the embroidery thread, and embroiders it on the base fabric through a computer flat-pole embroidery machine. It then melts the water-soluble non-woven base fabric through hot water treatment, leaving a three-dimensional Sensual lace.

Production process

Switzerland Take the imported Lixiu brand MD55 model as an example

- Pre-production:

1. Analyze ingredients and raw material specifications.

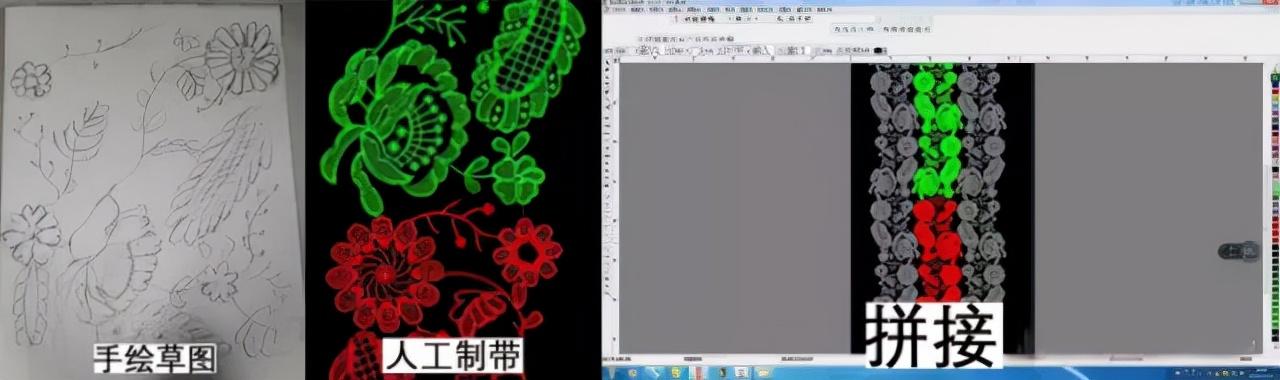

2. Make a computer blueprint “card tape”.

3. Proofer test quality ship sample

- Mid-production:

1. Before putting on the machine, remove the oil stains, lint, floatation and deep cleaning of the workshop.

2. Change the designated needle and thread if necessary.

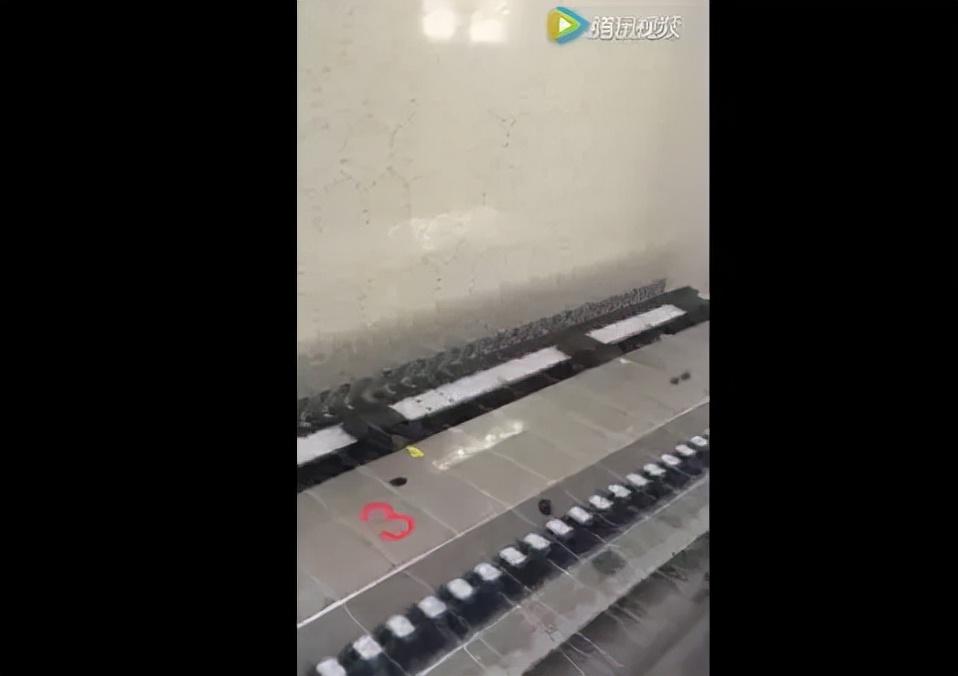

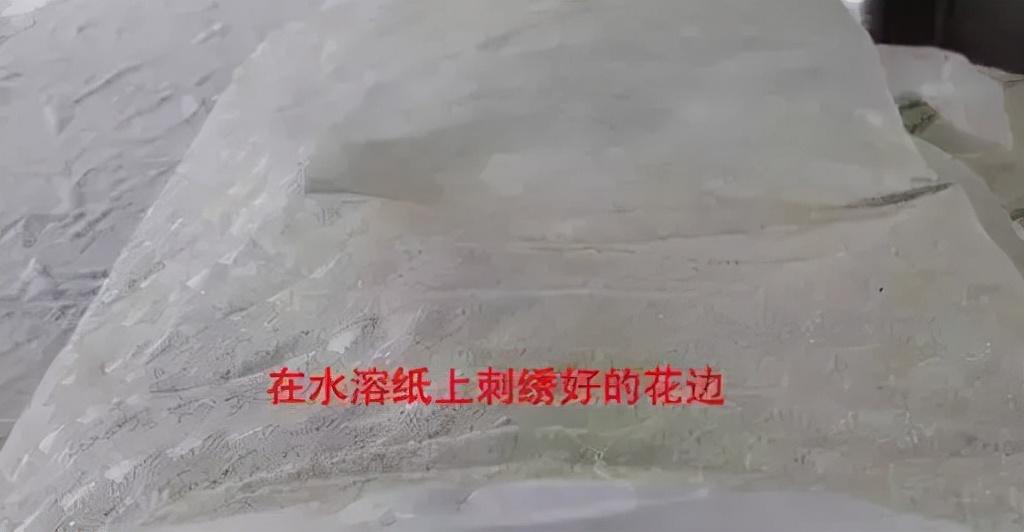

3. The machine for supporting water-soluble paper and corresponding base fabric starts working.

△The picture shows the lace machine embroidered on water-soluble paper

- Post-production:

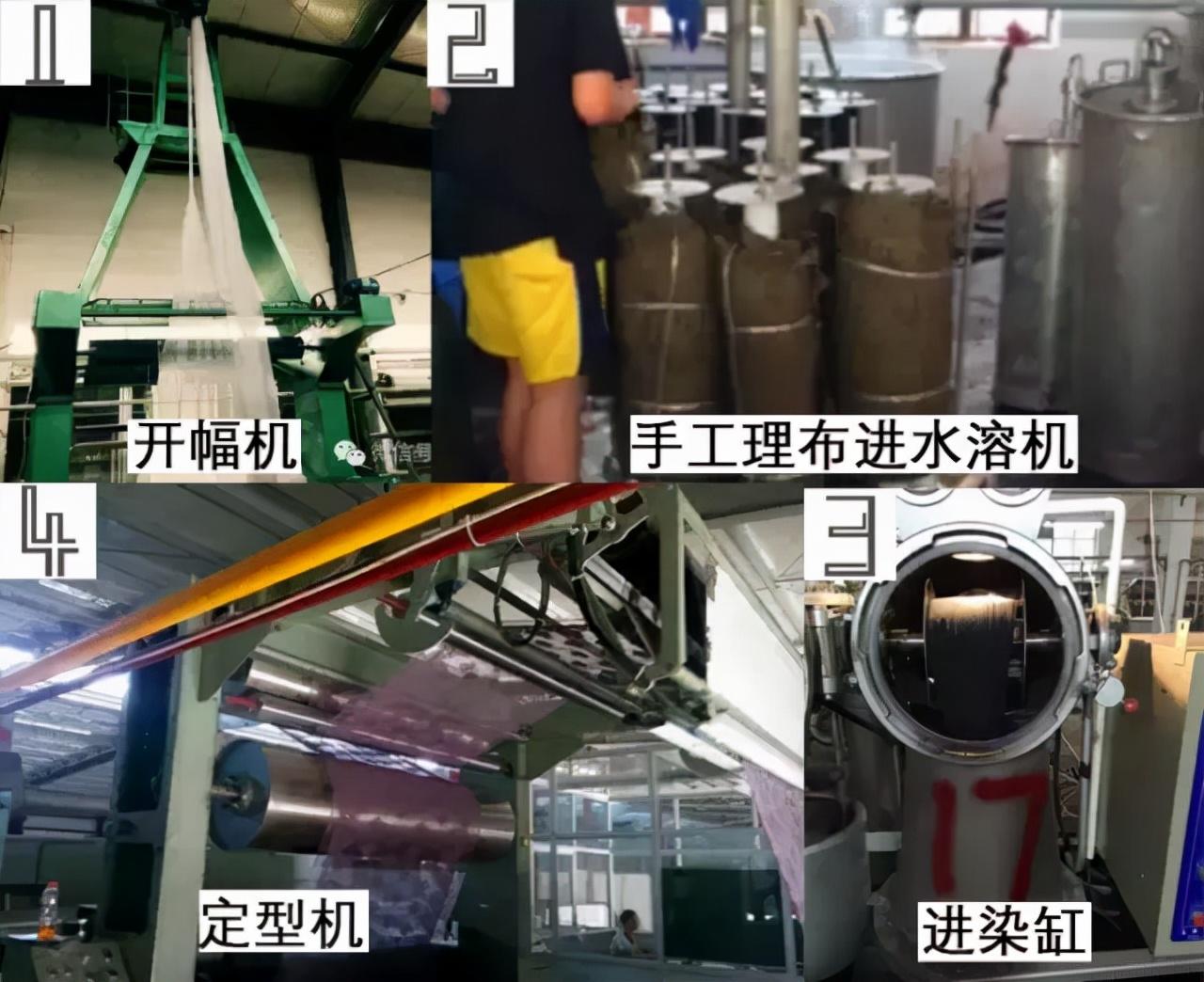

1. Water-soluble treatment, dyeing and shaping.

2. Manual embroidery at the end.

3. Cut the thread.

4. Trim the edges.

Features

Machine embroidery lace has many patterns, and the embroidery is exquisite and beautiful, even and uniform, the image is lifelike, full of artistic sense and three-dimensional sense.

The biggest difference between water-soluble lace and ordinary lace is that it is not “what you see is what you get” like ordinary plate making. It has to go through a process after it is completed on the machine. The “water boiling” process is what makes it possible to see that the needle processing when making water-soluble plates is different from ordinary plate making.

The difference between water-soluble embroidery and lace

Use one or several groups of parallel arranged yarns to feed all the working needles of the machine from the warp direction and form loops at the same time to form a knitted fabric. This method is called warp knitting, and the knitted fabric formed is called warp knitting. The knitted fabric formed is called warp knitted fabric. Warp knitted lace is strip lace and lace fabrics woven by warp knitting machines.

Difference

The similarity between water-soluble lace and lace at first glance is that they both have hollows. , but the obvious difference is that lace is generally thinner and the three-dimensional effect is not as good as water-soluble embroidery lace.