Developed by the Austrian company Lenzing as early as the 1980s, it is an early-developed new regenerated cellulose fiber. . Due to the high price of the fiber at that time and the fact that its performance was not fully understood, mass production has never been achieved.

Until the end of the last century, with the improvement of people’s living standards, the requirements for wearing comfort gradually increased, and underwear made of modal fiber entered the family. Just like Lycra labels in the past, Modal labels have become the new favorite of this era and are welcomed by consumers.

Modal is a new The high wet modulus viscose fiber is a new generation of regenerated cellulose fiber. The raw materials of this product are all natural materials. It uses European beech wood. It is first made into wood pulp and then processed into fiber through a special spinning process. , because more than 99% of the solvents used in the spinning process can be recycled, there is basically no pollution in the entire production process, it is harmless to the human body, and can be naturally decomposed and harmless to the environment. It is called green and environmentally friendly fiber.

Fiber properties

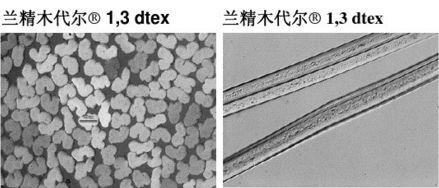

△The cross section and longitudinal surface of Lenzing Modal fiber

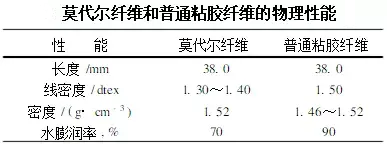

1. Physical properties

Modal fiber has a longer length, which makes Modal fiber have better yarn strength and evenness, less hairiness and smooth surface. Compared with ordinary viscose fiber, Modal fiber has better fineness and can spin finer yarns. The density of modal fiber is greater than that of ordinary viscose fiber, and its volume expansion rate when exposed to water is smaller than that of viscose fiber, which means that modal fiber is less affected by humidity than viscose fiber.

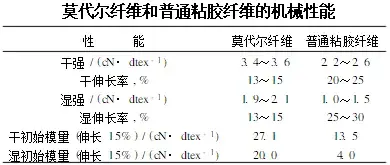

2. Mechanical properties

Compared with viscose fiber, the dry strength, wet strength and dry initial modulus of modal fiber and wet initial modulus are larger, while dry elongation and wet elongation are smaller, and various properties are less affected by humidity than viscose fiber.

The dry and wet strength of modal fiber is better than that of viscose fiber. Its high strength makes it suitable for the production of super Fine fibers. At the same time, the degree of fibrillation is small, which makes it have good spinnability and weaving properties.

3. Feel and gloss

The good appearance of Modal fiber makes The fabric has a silky luster, which greatly improves the quality of clothing; mixing modal fiber with cotton fiber will produce a luster similar to cotton mercerization process; modal fiber fabric is bright and bright; it is a natural mercerized fabric .

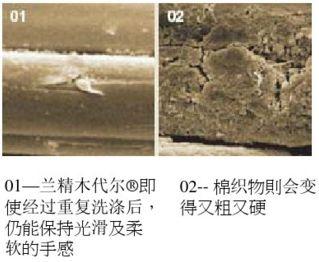

Modal fiber is fully refined and its longitudinal The cross-section structure is smooth, making it silky soft and smooth. The fabric feels particularly smooth, and you can feel its softness and smoothness when it comes into contact with the skin. The good feel and drape make the clothing more elegant, and the soft touch gives the fabric the reputation of second skin.

4. Dyeing performance

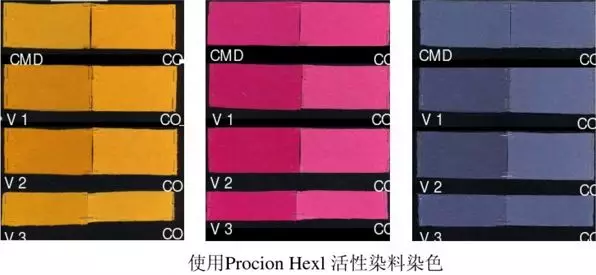

Dyeing mainly occurs in the amorphous region of the fiber molecular structure, which is related to the level of crystallinity of the fiber molecules. . Modal fiber has good dyeing performance, thorough color absorption, good color fastness, and bright and bright fabric color. As a kind of cellulose fiber, the dyeing performance of modal fiber is similar to that of viscose fiber and cotton fiber. Traditional dyes used for dyeing cellulose fibers, such as direct dyes, reactive dyes, vat dyes, sulfur dyes and azo dyes, can be used to dye modal fabrics. With the same dye uptake rate, modal fabrics have better colors and are brighter and brighter. . Modal and cotton blend��It is mercerized, and the dyeing is even and rich, and the color remains long-lasting.

CMD (Lenzing Modal), V1&V2&V3 (Viscose), CO (Cotton) Note: CMD (Lenzing Modal), V1&V2&V3 (Viscose), CO (Cotton)

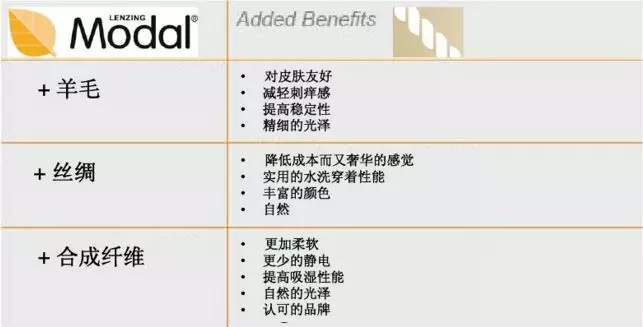

5. Blended performance

Modal fiber spinning can produce more uniform evenness, and can be blended with other fibers in different proportions, such as wool, cotton, linen, silk, polyester, etc. High quality yarn. The dry strength of Modal fiber is close to that of polyester, and its wet strength is much higher than that of ordinary viscose. Its gloss, softness, hygroscopicity, dyeability, and dye fastness are all better than those of pure cotton products; the fabrics made of it are better than those of pure cotton products. It has a silky luster, pleasant soft touch and drape, and excellent durability. Modal fiber can be blended and interwoven with a variety of fibers, such as cotton, linen, silk, etc., to improve the quality of these fabrics. This allows the fabric to remain soft and smooth, giving full play to the characteristics of each fiber.

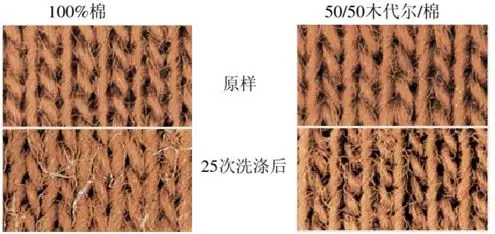

6. Stable performance

Modal fiber fabric has stable wearing performance, good garment effect, strong morphological stability, and natural anti-wrinkle It is non-iron and non-iron making it more convenient and natural to wear. After testing and comparison, after 25 washes with cotton fabrics, cotton fabrics will become harder and harder to the touch, while Modal fiber fabrics are just the opposite. They become softer and brighter the more they are washed.

The development and utilization of Modal fiber caters to People’s desire to “return to nature” and use natural fibers. The dry strength of Modal fiber is close to that of polyester, and its wet strength is much higher than that of ordinary viscose. Its gloss, softness, hygroscopicity, dyeability, and dye fastness are all better than those of pure cotton products; the fabrics made of it are better than those of pure cotton products. It has a silky sheen, a pleasant soft touch feel and drape, and excellent durability.

Modal is increasingly becoming an outerwear and decorative fabric s material. In order to improve the shortcomings of poor stiffness of pure modal products, modal can be blended with other fibers and achieve good results. Modal can also show its weavability during the weaving process, and can also be interwoven with yarns of other fibers to weave into a variety of fabrics.