I believe that many people are confused about the difference between nylon and polyester. How to identify and distinguish the two raw materials is a matter for textile people. This is an indispensable skill. After studying this article, you can also easily distinguish the composition of fabrics.

Part 1

Polyester

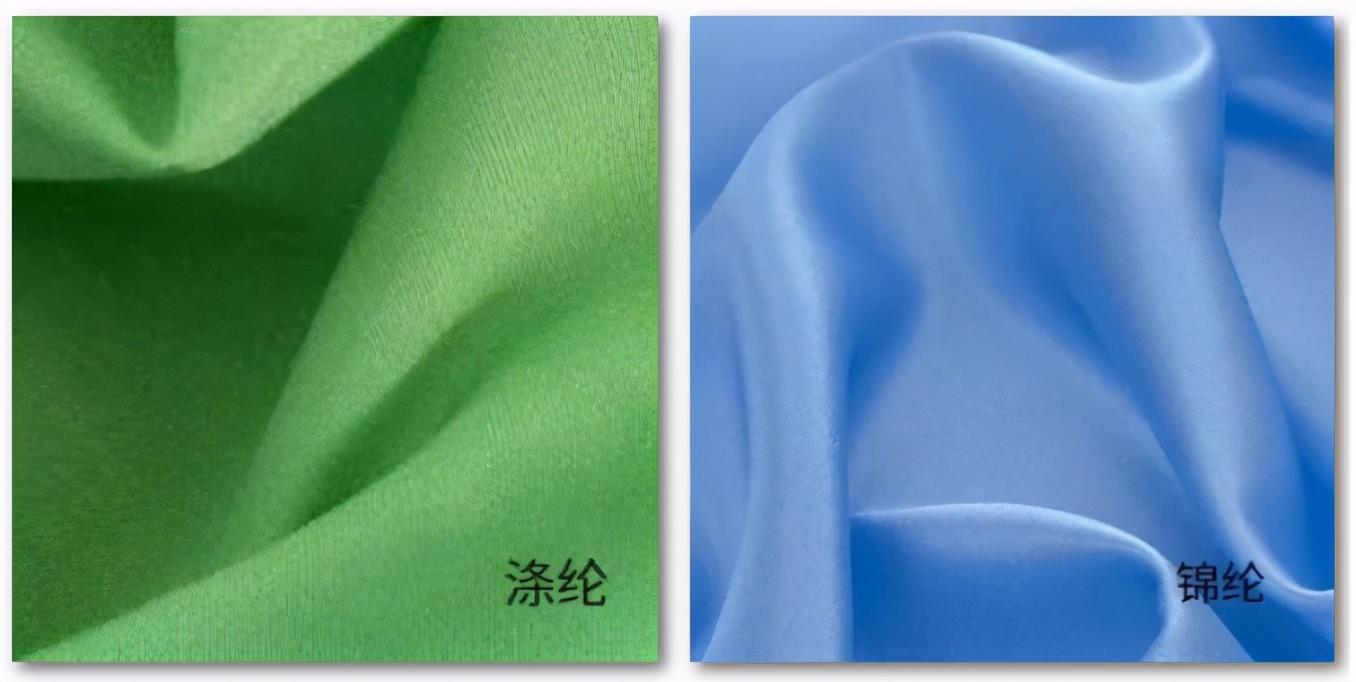

Polyester – Polyester fiber, also known as POLYESTER, is characterized by good breathability and moisture removal. It also has strong acid and alkali resistance and UV resistance. Generally, fabrics with multiples of 75D are polyester, such as 75D, 150D, 300D, 600D, 1200D, and 1800D. The appearance of the fabric is darker and rougher than nylon.

Part 2

nylon

Nylon – Nylon, also known as Nylon, polyamide fiber. The advantages are high strength, high wear resistance, high chemical resistance and good resistance to deformation and aging. The disadvantage is that it feels hard. The more famous one is PERTEX.

CORDURA. Generally, fabrics with multiples of 70D are nylon, such as 70D, 210D, 420D, 840D,

1680D is made of nylon, the fabric has a brighter gloss and a smoother feel.

Polyester V/S nylon

Nylon generally has better elasticity! The dyeing temperature is only 100 degrees! Dye with neutral or acid dyes. The height resistance is worse than polyester, but its strength is better and its pilling resistance is better! The dyeing temperature is 130 degrees (high temperature and high pressure), and the hot melt method is generally baked below 200 degrees! The main characteristics of polyester are better stability. Generally, adding a small amount of polyester to clothes can help with wrinkle resistance and plasticity. The disadvantage is that it is prone to static electricity and pilling. However, these shortcomings of improved polyester have been improved.

|

Polyester |

Nylon (nylon) |

|

|

Mechanical Properties |

High breaking strength, large elongation; initial modulus High; good elastic recovery; stiff fabric, good wear resistance and good dimensional stability. |

High breaking strength and buckling strength, large elongation; initial The modulus is low, the work of rupture is large; the elasticity is good, the wear resistance is good, the shape retention and stiffness of the fabric are poor, and the stiffness is poor. The abrasion resistance, stress resistance, color fastness, gloss and other aspects are better than polyester products, and it is not prone to dead wrinkles. The main difference between fabrics made of polyester and fabrics made of nylon is: ① The price of nylon is about 1 times higher than that of polyester. ② Nylon is smoother and softer than polyester. ③ The wear resistance is almost the same. ④ Nylon has a little elasticity. Polyester is not weak sex. ⑤ Nylon dyeing is more difficult than polyester dyeing. Material related indicators D:denier, T:tex, referred to as “tex”, is a unit used to measure the density of textile fibers. It refers to the weight in grams of a 1,000-meter-long fiber or yarn at a common moisture regain. The formula T=G/L*1000. That is fiber weight/fiber length*1000. TX = Shrink treatedRS = Tear resistantN = NylonP = Polyester

TXN 500:A fabric made of nylon fiber with a tight texture, used for alpine hiking and light-weight backpacks. RSN 500 GRID: span>It is a fabric woven by adding TXN 500 fabric with black anti-tear fiber. ��On medium and large backpacks to reduce the weight of the backpack.

This article is from the Internet, does not represent 【www.garmentmanufacture.com】 position, reproduced please specify the source.https://www.garmentmanufacture.com/archives/6458

|