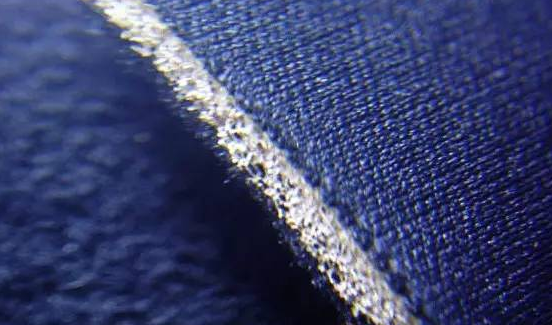

Composite fabrics can be used to make clothes, sofas, bedding, etc., and are increasingly used in our lives.

Composite fabric Lamination Fabric, Soft Shell Fabric

Composite fabric is a new type of material made by bonding one or more layers of textile materials, non-woven materials and other functional materials. Suitable for sofas, clothing and other textiles.

Composite fabrics use “new synthetic fiber” high technology and new materials, and have many excellent properties (compared with ordinary synthetic fibers), such as fabrics that are clean, delicate, elegant, and warm. It has a plump appearance, is windproof, breathable, and has a certain waterproof function. Its main features are warmth and good breathability.

Classification of composite fabrics

Composite fabrics are further divided into ordinary composite fabrics (made by bonding fabrics and linings with adhesives to improve the texture of the fabric and are suitable for garment processing) Simplification and large-scale production) and functional composite fabrics (composited fabrics have special functions such as waterproofing, moisture permeability, radiation resistance, washing resistance, and wear resistance).

Two-layer composite fabric and three-layer composite fabric❂ Two-layer composite fabric

The two-layer composite fabric is composed of outer fabric and TPU, PTFE film Made of polyester, nylon or nylon-poly blended fabric, the outer layer is soft to the touch, wear-resistant, tear-proof, has good color, has excellent waterproof, breathable, windproof effects and long durability. The surface of the fabric is treated with Teflon water-repellent treatment.

Schematic diagram of two-layer fabrics

When using two-layer composite fabrics to make garments, a lining should be hung, or a fleece thermal layer should be used as a jacket.

Technical performance of two-layer composite fabric:

Water pressure resistance>10000mm

Moisture permeability>5000g/m2.24h

Windproof>100%

Applicable scope: skiing, cycling, backpacking, mountaineering, golf, casual wear, etc.

❂ Three-layer composite fabric

Three-layer composite fabric is made of outer fabric, e-PTFE film, and inner warp-knitted mesh. There is no need to hang the lining when making a ready-to-wear garment. The outer fabric is made of polyester, nylon or nylon-poly blended fabric, which has a light and thin feel, is tear-resistant, wear-resistant, has good color, has excellent waterproof and windproof effects, better breathability and long durability. The surface of the fabric is treated with Teflon water-repellent treatment.

Three-layer fabric schematic

Three-layer composite fabric uses special technology and equipment to combine 100% pure polyester thickened high-strength non-woven fabric and polytetrafluoroethylene Made of ethylene (PTFE) microporous film composite laminated, it has many functions such as virus blocking, antibacterial, anti-static, anti-blood penetration, waterproof, moisture permeable, windproof, and warmth retention. It is also comfortable and lightweight to wear. The anti-microparticle transmission rate is over 90%, making it impossible for viruses and bacteria to pass through.

Technical performance of three-layer composite fabric:

Water pressure resistance>10000mm

Moisture permeability>6000g/m2.24h

Windproof Safety>100%

Application scope: skiing, cycling, backpacking, mountain climbing, etc.

Composite Technology

There are six internationally popular composite processes, namely Hot Sol Powder Dot Coating Composite Technology, Hot Sol Slurry Dot Composite Technology Process,Hot sol powdering composite process,Hot sol two-point composite process,Polyurethane spray composite process,Polyurethane roller coating composite process. In the past, the more common composite was the composite of suede fabric and wool. Nowadays, any fabric can be used to laminate together.

The door width of composite fabrics is limited to the size of the two fabrics before they are combined, which can generally reach 145CM. If it is a composite of knitted fabrics, the width of the knitted fabric will be wider than that of cotton woven fabric.

The composition equation of composite fabrics:

The finished products purchased from the two fabrics ① Composite film factory ② Mid-term maintenance and processing factory ③ Post-finishing factory ④ Fabric completed

Each batch of composite fabrics must be effectively maintained. First, laminate the reverse fabric (the film is a transparent material similar to nylon film), bond it with chemical materials, and then perform maintenance treatment. The time of maintenance treatment The longer it is, the better the bonding fastness to the fabric and the degree of fusion of the adhesive will be. Generally, domestic adhesives require three days of maintenance, and imported adhesives require five days or more. The time required for the adhesive to fully integrate into the fabric and membrane will also affect the subsequent and front-facing processes. The effect of fabric bonding.

The maintenance and processing workshop is completely closed. A certain temperature and humidity must be maintained indoors to allow the adhesive to fuse naturally. If the temperature is increased in order to complete it quickly, it will speed up the operation process of the finished product. , but defects often occur. For example, during the sewing process of the finished fabric, the yarn of the fabric is broken by needles, and the feel becomes hard, and there is a rustling sound when rubbing against each other, indicating that the adhesive is solidified on the fabric and the fabric is damaged. The yarn becomes stiff.

After the maintenance treatment is completed on the reverse side, the front fabric is laminated, and the same maintenance treatment is required. It is worth noting that when the front side is laminated, the front and back fabrics should be aligned with the silk strands to avoid serious problems. Weft skew, straight yarn twisting and other phenomena.

It needs to be emphasized that the composite fabric cannot be re-composited, even if materials are used. Stripping also greatly affects the yarn of the fabric, making it harder and harder, and the fabric is very susceptible to needle puncture when sewing into the garment.

Since the film adhesive uses chemical materials, it will have a certain physical reaction to nylon fabrics. Therefore, it is recommended that customers use polyester fabrics, which can effectively control the color of the fabric before lamination and the color after lamination. , as well as water pressure resistance and breathability index have a certain impact.