The raw material for making triacetate fabric isConiferous trees growing in Canada and Alaska span>Semi-synthetic fibers from natural wood pulp,It is a pure version of man-made fiber.

This fabric was originally developed in Japan. New technological fabrics, and the softness of the fabric is comparable to that of natural fibers, and its function is more effective Comparable to man-made fibers.

Acetate , also known as acetate fiber, is one of the earliest chemical fibers developed in the world. It is currently the second largest variety of regenerated cellulose fiber after viscose fiber. Cellulose acetate is made from cellulose pulp, which is acetylated to form cellulose esterified derivatives and then dry-spinning.

You must know that early acetate fiber developed very slowly because it was difficult to dye it with common natural fiber dyes, which limited its application in the textile field. It was not until 1954 to 1955 that cellulose triacetate was successfully industrially produced by certain companies in the United States, the United Kingdom, Canada, France and Germany.

Currently, there are more than 20 acetate fiber manufacturers in the world, located in Belgium, Brazil, Bulgaria, Colombia, Italy, Mexico, Uruguay, Canada, Germany, the CIS, Japan, the United Kingdom, and the United States, but the production technology is monopolized by a few countries.

my country’s acetate fiber industry began in the 1950s. It has developed slowly, the production technology is relatively backward, and the varieties are limited to acetate tow for cigarettes. Textile fiber acetate has relied on imports over the years, mainly from four major companies: Celanese Corporation of the United States, Contex Corporation of the United Kingdom, Celanese Corporation of Canada, and Mitsubishi Corporation of Japan.

Common acetate fiber basically has good thermoplasticity, excellent dyeability, and is not easy to Anti-static and other advantages.

The Japanese triacetate fabric mentioned at the beginning of the article has the following advantages.

1. Japanese triacetate fabric with crisp drape ensures high-end texture and smooth lines. It is a high-end commuting fabric in the new era.

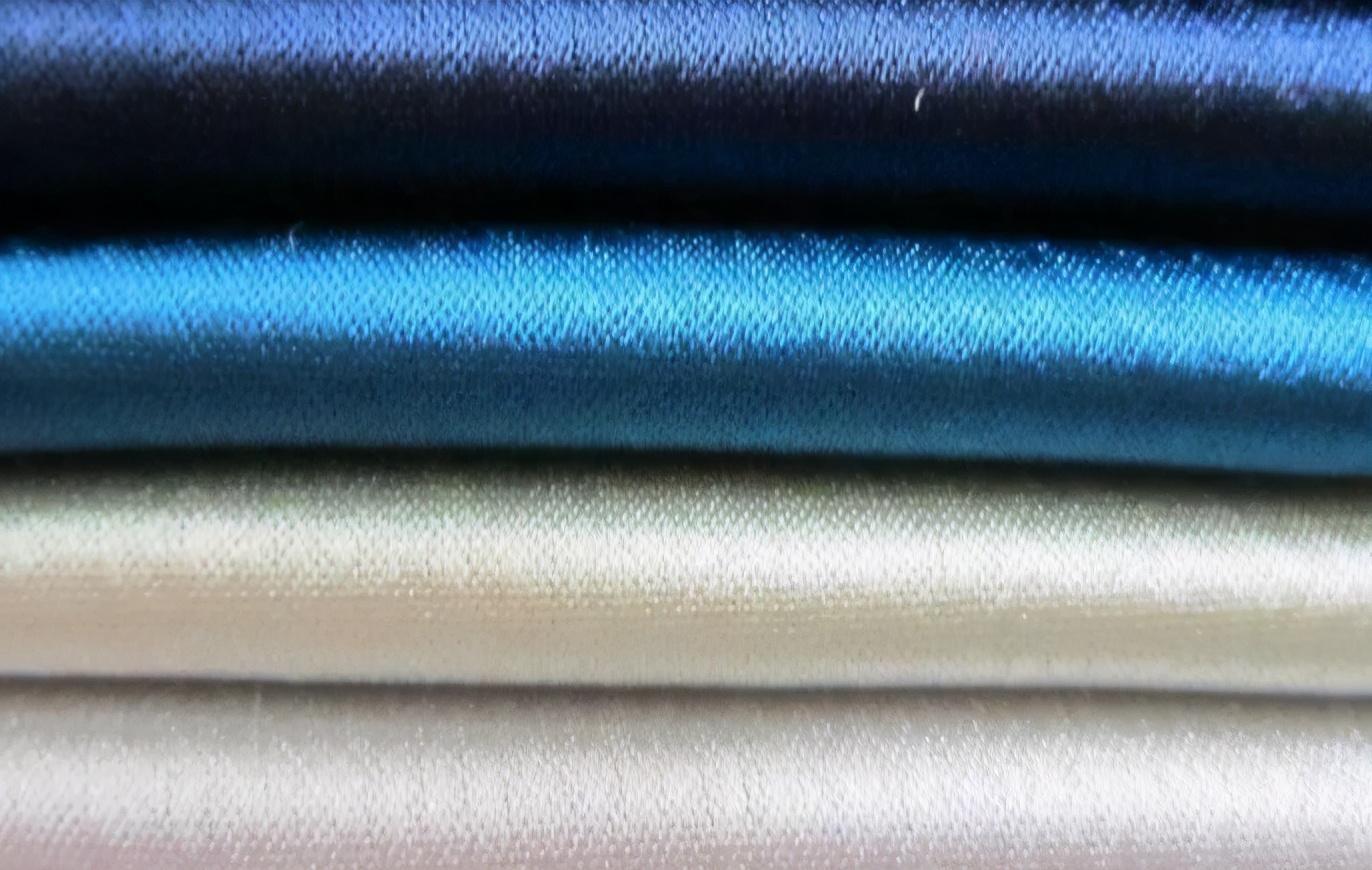

2. The texture is high-end and the texture is exquisite. This is mainly due to the fine yarns and the texture that is closely interwoven through a special weaving process. Therefore, the texture is beautiful and the texture is high-end and clean. Good gloss and texture,

3. Easy to take care of. It is resistant to wrinkles and deformation, and has a smooth and high-quality feel. For office workers who sit for a long time, they don’t have to worry about creases when wearing it.

4. The upper body does not absorb sweat like fiber and has strong breathability.

5. It is skin-friendly and cool, and feels refreshing and comfortable on the body. It is a thickness that can be worn in spring, summer and autumn.

Because of these reasons, the price of acetic acid fabrics is basically a bit expensive.

In addition, because clothes made of acetic acid fabrics are basically not acid-resistant, although it can actually be dry-cleaned or washed, when washing, try to It is better to use neutral detergent or silk wool detergent.