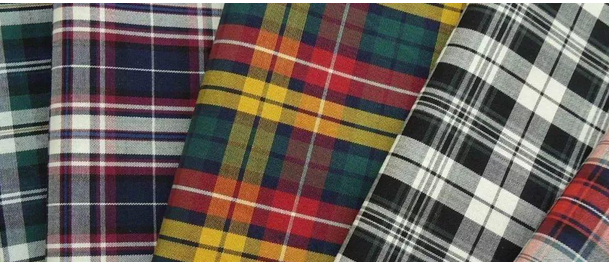

Yarn-dyed, yes It refers to the process of dyeing yarn or filament first, and then using the colored yarn for weaving. The colors of yarn-dyed fabrics are mostly bright and bright, and the patterns are also distinguished by color contrast.

Advantages:Yarn-dyed fabrics utilize different colors The yarns and fabrics cooperate to form various beautiful patterns, which are more three-dimensional than ordinary printed cloths.

Because the yarn-dyed fabric is dyed with raw yarn and has strong dye penetration, The color fastness is good.

Dy-dyed fabrics are weaved using multi-shuttle and dobby weaving, which can Interweave different fibers or different yarn counts into varieties with rich colors and clever patterns.

Because yarn-dyed fabrics use colored yarns or patterned yarns and various The structure changes, so poor quality cotton yarn can still be woven into beautiful varieties.

Disadvantages:Due to the large losses in yarn dyeing, weaving, finishing and other processes, Taiwan’s production is not as high as the output of white gray cloth, so the investment cost is high and the technology is High standard.

Yarn-dyed fabric is made of dyed yarn. Yarn dyeing is generally divided into two methods: color spinning and dyeing yarn. It is usually called yarn-dyed weaving. Cloth refers to cloth woven by shuttle looms, but knitting machines can also make yarn-dyed knitted fabrics. Compared with printed and dyed fabrics, it has a unique style, but the price is more expensive. The total loss is relatively large, and the output produced in Taiwan is not as high as that of white gray cloth, so the cost increases.

Features:The color fastness is better, because it is dyed with yarn first, and the color will penetrate into the yarn. Generally, when you peel off the yarn of printed and dyed fabrics, you will find that Some places are not colored. Minimum order quantity is small. No matter what yarn weave, density, texture, or color, it can be made from tens to hundreds of meters. However, it is difficult to specially customize dyed printed fabrics without gray fabrics, and the dyeing and printing process will also limit small batch production.

All-color weave:There are dyed or partially dyed yarns in the warp and weft (or there are several colored yarns interwoven with white yarns in the fabric).

Half-dyed weave: The warp or weft yarns are dyed or partially dyed, and the gray yarn cannot be used to weave yarn-dyed fabrics because the gray yarn The tension and shrinkage of yarn are different from those of dyed yarn, so it certainly cannot be used in the warp direction. When used in the weft direction, the cloth surface will be deformed due to shrinkage issues during finishing. Therefore, generally colorless yarns are semi-bleached or fully bleached.

Difference

1. All-dyed weaving

A: In order to achieve different color effects – it is impossible to dye the same raw material with different colors after printing and dyeing, so we use Yarn-dyed fabrics can��to

B: Requirements for color fastness and shade – yarn-dyed products have good color fastness and good shade feeling

C: Requirements for layering ——Requires a good sense of layering

2. Half color Weaving

Differences in warp and weft raw materials – using warp Different weft yarn raw materials have different performance requirements for dyeing. Semi-dyed weaving can be used to reduce costs and increase styles

In fact, it is very simple to judge whether the fabric is yarn-dyed fabric

Basically two or more colors and the same composition (such as 100% cotton, 100% polyester) are basically yarn-dyed fabrics. If it is a plain color, it depends on the quality and color fastness of the fabric. Generally, the quality of plain fabrics made from yarn-dyed fabrics is better than that of dyed fabrics. The fabric surface is fresh and the lines are clear. The fastness is also higher than that of dyed cloth

There is another way to distinguish, When dyeing fabrics, you need to weave the fabric first and then dye it. However, when it comes to yarn-dyed fabrics, you dye the yarn first and then weave the fabric. Therefore, generally when it comes to yarn-dyed fabrics and dyeing, just look at the front and back sides. If that doesn’t work, just draw the yarn. If the threads are the same color inside and out, it is yarn-dyed fabric, but if the outside surface has a layer of color, it is dyed fabric.